Models: All

Condition

Caliper and hose replacement does not cure brake pull

Repair Procedure

Repair Procedure

Sticking caliper pistons, rusty brackets and bad brake hoses can all cause brake pulls, but don’t assume they are the only things that can.

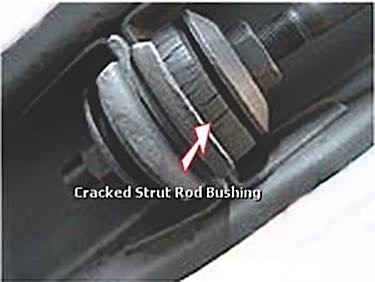

If the problem is constant pull, it is typically easier to diagnose. Don’t forget to inspect suspension parts, such as bushings, that allow wheel movement under braking.

The harder diagnosis is the intermittent pull that may not have any pattern. If you can duplicate concern in the shop, process of elimination is your best choice. Let’s say the vehicle pulls right, you crack open the left front bleeder and nothing comes out. Work your way upstream until you find pressure. If you work all the way up to the ABS hydraulic module and you still have no pressure, you probably have a valve hanging up in the unit. We talk to technicians every week who are finding just that. Pushing the piston back into the caliper during routine brake service may contribute to problems, but so can hygroscopic brake fluid. Moisture causes rust, even inside the brake components, which can cause valves to stick or not seat properly. Sometimes a thorough brake flush may work along with valve actuation via a scan tool or road test. Don’t forget, many vehicles are split diagonal so testing both corners may reveal a bad master cylinder.

If the pull only occurs after the vehicle has been driven a while, it may be heat-related. Using a non-contact thermometer after a road test may help identify the cause. If both rotors are similar temps, it may be a control arm bushing getting soft from the exhaust manifold or converter.

Diagnosing and correcting brake pulls should include a complete brake, suspension and steering check along with a TSB search. The manufacturer may have already solved the problem. Recommending brake fluid service may also prevent expensive ABS repairs at a later date.

Courtesy of Raybestos Brakes.