As a tech, you’re familiar with one of the most common reasons customers bring their vehicles into the shop: unpleasant noise emitted when they press down on the brake pedal.

The key to managing brake noise is to first determine where it’s coming from and what could be causing it, which means checking several different elements of the braking system (and even the vehicle as a whole) before making your diagnosis.

Common Brake Noise Issues

Shuddering

Sound that results from a vibration in the braking system, sometimes referred to as brake shudder, can be caused by damaged brake rotors, malfunctioning brake calipers or simply from brake pads that have not been properly worn in yet. Check out our how-to article on properly bedding-in new brake pads and brake rotors here.

Grinding/Squealing

If your customer says their vehicle is emitting a grinding or a squealing sound – especially when they first get into their car in the morning – it may be helpful to ask them where they park their vehicle at night to better determine next steps.

Drivers that park outside may be experiencing a buildup of rust on the brake rotors due to temperature and moisture changes at night. If this is the case, the brake noise should cease as they day goes on with regular driving. This specific type of brake noise is sometimes referred to as “morning sickness.” Recommending that your customer parks their vehicle in a garage if possible – especially when it rains, snows or is humid – can help eliminate this issue in the future.

Ways to Mitigate Brake Noise

One method that can help resolve brake noise issues is to ensure that the braking system is properly lubricated. To do this, you’ll need to remove the brake pads from the calipers and apply lubrication to areas like the back of the brake pad and to the caliper carrier.

Remember, a little lubrication goes a long way, so it’s important to avoid getting lubrication on the brake pad surfaces or rotors.

Another technique to help solve brake noise issues is cleaning the calipers, which can be done by using a wire brush to clear away any rust.

Proper fitment is important too, so checking that there are no gaps between hardware components is imperative. Gaps in braking system parts can cause unusual sounds when driving and impact the braking experience for the customer.

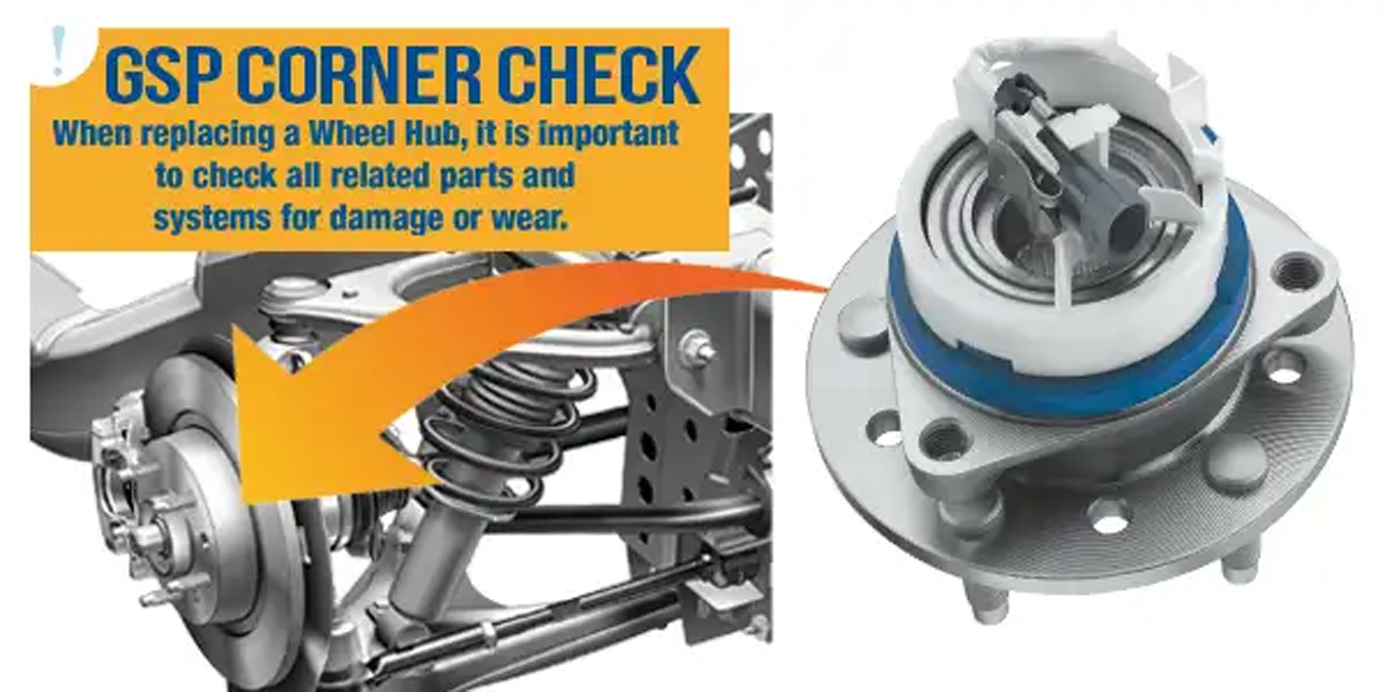

If you’ve tried the suggestions above and the problem persists, it’s time to look beyond the braking system. Inspecting non-brake system parts like the vehicle’s wheel bearings, steering, chassis and suspension components can help you determine if the brake noise issue is the result of a more serious problem within the vehicle.