Buying a quality brake pad is like purchasing medicine. When you buy a legal drug, you are not just paying the cost to manufacture, package and market the pill. The bulk of what you are paying for is research and development. The same is true for brake pads.

BACKING PLATES

The backing plate creates a foundation for the friction material that must be stiff and stable. If a backing plate flexes, the friction material is not in full and even contact with the rotor. This movement can cause longer stops, a softer brake pedal and the potential for unwanted noise.

Look at the thickness of the backing plate and the edges. A poorly stamped backing plate will have rough edges. Also, look at the areas where the pad contacts the caliper and bracket. These areas should be as smooth as possible.

The attachment method of friction to the backing plate does matter. For some fleet and safety-critical applications like school buses, the manufacturer or insurance company may specify a brake pad that uses a mechanical attachment to secure the backing plate’s friction material. Mechanical attachment involves some type of protrusion from the backing plate to hold the friction material. Some backing plates have tiny hooks machined into the surface to hold the material. Other mechanical attachment methods can use welded mesh and posts.

Corrosion Qualities

Many pads use a protective layer of paint or powder coating to protect the backing plate. This is applied after the friction material is mated with the backing plate. This protects the exposed metal surfaces. Galvanization is a plating process in which an outer layer of zinc and other metals is applied to the backing plate by a process called electroplating or electrode position. This bonds the galvanized layer to the backing plate at the atomic level.

Galvanization is done before the friction material is attached to the backing plate. By galvanizing the surface between the backing plate and friction material, the possibility of corrosion that can cause edge lift and delamination is eliminated.

Hardware

Hardware is a broad term that covers abutment clips, anti-rattle clips and much more. When you buy better brake pad sets, the quality and completeness of the brake hardware improves.

The first improvement is the material used for the hardware. Low-quality brake hardware might use a plated or coated steel. Better hardware uses stainless steel. This upgrade yields a more corrosion resistant surface. Some premium pad lines might use layered materials that can dampen noise and vibration.

Hardware also includes brake shims. Brake shims prevent and reduce the transmission and amplitude of vibrational forces that cause excitation of the caliper, pad assembly and attached structure. These vibrations are very small and a properly engineered shim can isolate a vibration before it excites the caliper and knuckle. On premium pads, this is accomplished by viscoelastic damping material that is a sandwich. These shims prevents vibrations that start at the pad and rotor from being transferred into the caliper and knuckle.

Friction Materials

Friction materials are difficult to classify as premium just using your eyes. Also, most friction material engineers would tell you classifying friction materials and ceramics being the best and non-asbestos organics as the worst, simply does not work because all the other ingredients in the mix have just as much influence over the performance on the vehicle.

The structural properties of a ceramic material are very stable under high temperatures, much like Corning cookware. But this is where the comparison breaks down. The ceramic materials that go into a brake pad are very small strands that are engineered to be a certain length and width. Since the ceramic materials offer stable performance under a wide range of temperatures, they offer quiet performance.

Semi-metallic pads incorporate metal fibers to provide structure and friction characteristics. The metals used are typically high-quality steel, copper and other exotic metals. Semi-metallic pads can be found on many different applications, from sports cars to luxury SUVs.

Non-asbestos organic (NAO) friction materials are difficult to classify because the name invented when many manufacturers shifted away from asbestos fibers in brake pads. Technically, ceramic friction materials could be classified as NAO material.

What makes one friction material quieter or better than another? It’s a two-part answer. First, if a friction material is better at keeping a constant coefficient of friction across broad temperature ranges and environmental conditions, it’s probably a quiet pad. A “consistent” friction material causes less variation in vibrational excitation at the friction coupling by having consistent brake torque at environmental extremes.

Second, some friction materials leave or transfer a layer of friction material (transfer film or “seasoning”) on the rotor’s surface that some friction material companies claim can smooth out the rotor surface, thereby causing less excitation and noise at the friction coupling. Also, this transfer layer may not be as sensitive to heat-induced brake torque variation.

These two performance parameters are dependent on the application. This means that the friction is formulated are specific criteria about the application. This is why some friction material lines have only one brake pad formulation for an application. You don’t have to choose between different formulations.

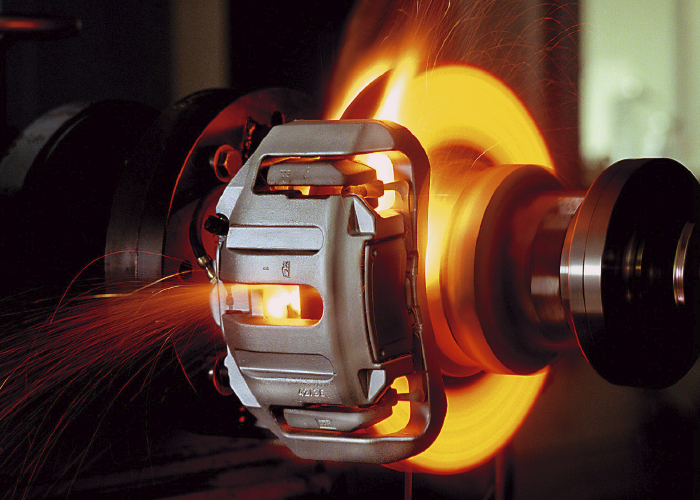

When an aftermarket brake pad manufacturer is developing or reverse-engineering an application, rarely do they test on an actual vehicle. This type of testing is expensive and time-consuming, and the human element can alter the results. On the other hand, a brake dynamometer can test brake systems in a controlled environment that mirrors the real world. It can run 24 hours a day and measure the performance of a braking system over its entire lifetime.

A brake dynamometer is also more sophisticated in that it can simulate the conditions the brake system will experience in a much shorter time. This means that a brake dynamometer can simulate the mass, inertia and performance capabilities of a vehicle.

In the engineering world, there is a saying that goes: “One test is worth a thousand expert opinions.” This saying is also true for the brake technician.