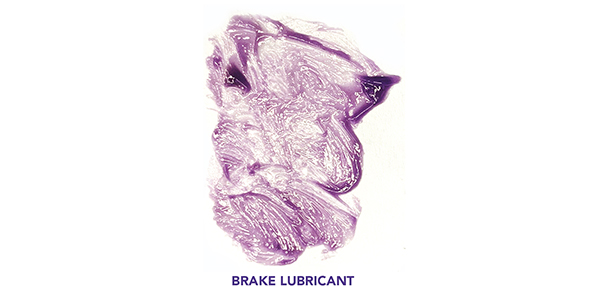

If you walk away with one thing from this article, it is this: Brakes are the hottest components on a vehicle and they need lubricants that can stand up to the heat. With inconsistent temperatures, brake lubricant also needs to work at sub-zero as well as scorching temperatures.

The front brakes on many front-wheel-drive cars and trucks can easily reach several hundred degrees with normal braking, and get much, much hotter under certain circumstances. Riding the brakes in heavy stop-and-go traffic, mountain driving, aggressive driving, towing a trailer, or hauling a heavier-than-normal load can all increase the load on the brakes and the operating temperature of critical brake components.

At these elevated temperatures, most chassis or general-purpose greases intended for ball joints and wheel bearings can’t take the heat and will either melt or burn off, leaving surfaces unprotected and unlubricated. Worse yet, the grease may contaminate the brake linings if it melts and runs off the calipers or drum hardware. That’s why high-temperature specific brake lubricant works best for brake system applications.

Another reason for not using ordinary chassis grease or multi-purpose grease on brake components is because these products are usually petroleum-based. As every technician should know, many petroleum-based products are not compatible with the seal materials that are commonly used inside brake systems. Petroleum-based grease or oil should never come into contact with the rubber seals, pistons or other internal parts in a master cylinder, brake caliper or wheel cylinder. If it does, the entire brake system should be considered contaminated. Why? Because petroleum-based products can cause incompatible seal materials to swell, rupture and leak, which could lead to fluid loss and brake failure.

Brake lubricants are specially formulated products that are designed exclusively for brake applications and nothing else. The chemicals in these products are compatible with all commonly used materials in brake systems.

TYPES OF LUBRICANTS

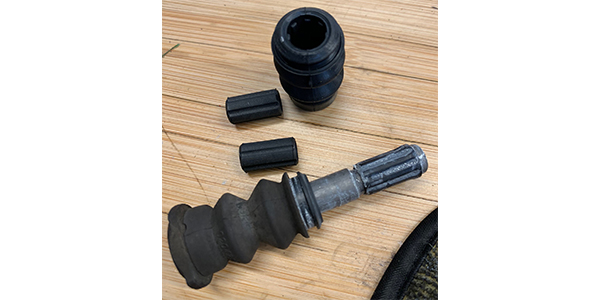

There are two basic categories of brake lubricants. First, there are lubricants that are designed to lubricate the guide pins and slides. These lubricants are contained inside boots and caps.

These lubricants keep a floating caliper moving freely. They may look like grease, but they are synthetic and might have lithium, silicone or ceramic listed in the ingredients. These lubricants are also compatible with rubber so it will not damage boots and bushings.

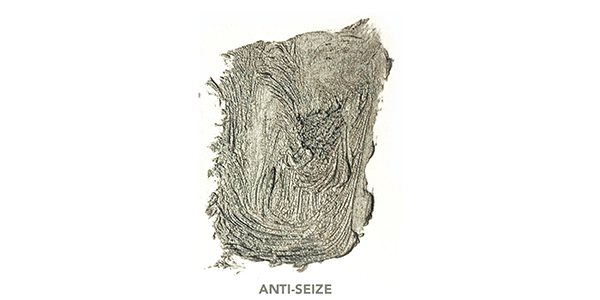

The other category is boundary-layer lubricants. These lubricants can be used in areas where two metal surfaces move against each other. These surfaces include brake pad ears, abutment clips and shims. These have high-solid content and typically contain a variety of friction-reducing ingredients such as molybdenum disulfide (“moly” or MOS2), graphite or copper. These are often called “anti-seize” lubricants.

Versatile boundary-layer lubricants can handle high temperatures and pressures. Some of these products are rated to withstand intermittent temperatures as high as 1,400 degrees F. The main advantage of these lubricants is that they will not be easily washed away by water or attract debris. Some products can be used for both slides and exposed surfaces.

Keeping the brake parts moving prevents noise. When a brake pad is applied to a rotor, it creates a vibration. That thin layer of lubricant between a brake pad and caliper or bracket can prevent that vibration from transferring to the caliper, knuckle or strut.

If vibration is transferred, it changes in frequency due to the different masses of the components. The change in the frequency of the vibration could cause noise in the range of human hearing. This is called force-coupled excitation by engineers.

The key to improving the performance of any brake lubricant is to read the directions on the side of the bottle or tube. Another piece of advice is to never use excessive amounts of a product. Too much grease inside a slide boot could cause brake drag as the grease heats up and expands. Also, too much lubricant can cause contamination of the braking surfaces.

If you apply any friction-modifying substance, like oil or anti-seize to the threads on the caliper, bracket or lugs nuts, it is going to change the measured torque values. This is because the threads use friction between the two fasteners to clamp the two parts together. With less friction on the threads, torque values increase.

So, when you tighten a wheel to 85 ft.-lbs, it may actually be torqued at 95 ft.-lbs (this includes torque wrenches and sticks) or more depending on how slick the lubricant was that was put on the threads.

The increase in force will mean that the studs will stretch under the increased torque. This stretching can lead to metal fatigue and changes in thread geometry. The Subaru driver had the car for three years. After a few tire rotations and maybe a few too many hits with an impact, the stud was ready to break.