Don’t miss a worn joint!

Detecting and measuring wear in a ball joint is critical to ensuring the safety of a vehicle.

Types of Ball Joints

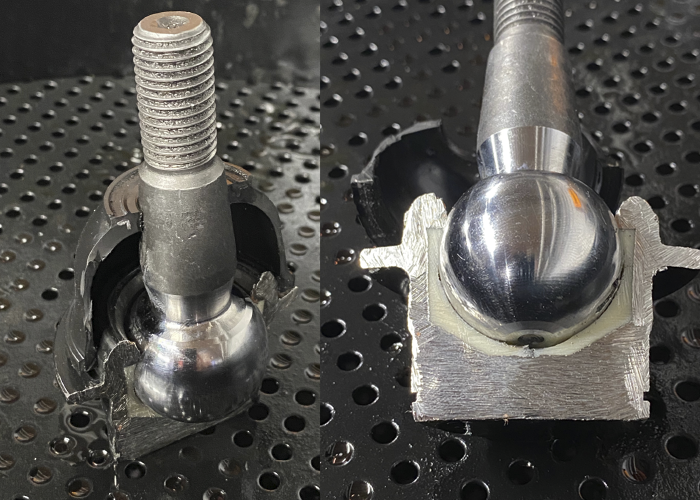

A ball joint is made up of a housing, ball stud, bearings, end cover and Belleville washer or spring. A Belleville washer is a conical-shaped spring designed to be loaded in the axial direction. The joint is attached to a control arm by pressing or riveting the joint into the arm. If the joint is pressed into the arm, it will require a special tool to remove the old joint and install the new one.

Failed pressed joints can be difficult to remove because of corrosion between the control arm and joint. This is especially true when a steel ball joint housing is pressed into an aluminum control arm.

When the joint is riveted to the control arm, the rivets are drilled out or cut with an air chisel. The new joint is replaced using bolts and locking nuts.

1) Loaded Joint: A loaded joint is designed to support the weight of the vehicle and a follower joint that positions the control arm or strut assembly.

A lower control arm that is connected to the spring uses a loaded ball joint to connect the steering knuckle to the upper control arm follower ball joint in an SLA suspension. The ball joint also allows the steering linkage to rotate the steering knuckle.

2) Follower Joint: A strut suspension uses a follower ball joint to connect the lower control arm, steering knuckle and the strut. The upper strut mount assembly usually contains a thrust-type bearing to support the weight of the vehicle and allow the steering linkage to rotate the strut and steering knuckle.

Bearing the Load?

Ball joints can be broken down into the load-bearing and non-load-bearing categories. A load-bearing ball joint is designed to support the weight of the vehicle while providing a hinge point for the steering system. Most load-bearing ball joints are designed to cancel the effects of normal wear by centering themselves in their own sockets.

Non-load-bearing ball joints, on the other hand, are designed to maintain precise dimensional tolerances in a steering or suspension system. Wear in a non-load-bearing ball joint will cause a noticeable change in the camber, caster or toe angle of a front suspension. Consequently, non-load-bearing joints are preloaded in order to compensate for wear. Unloaded control arm ball joints, for example, should be tested for preload when the suspension system is disassembled.

Ball Joint Wear

Some ball joints that have a grease fitting use the fitting as a wear indicator. If a grease gun will not couple to the fitting, the joint needs to be replaced.

As the joint wears, the Belleville washer or spring sustains the tension on the bearings to maintain zero axial endplay as the control arms move — the Belleville washer or spring will not compensate for lateral wear. Lateral wear causes the ball stud to move inside the bearing, which can affect camber and tire wear.

Performing an Inspection

Loaded Joint: To check a loaded ball joint, place a jack or jack stand under the lower control arm to support the weight of the vehicle. Attach a dial indicator to the lower control arm and locate the dial in a vertical position to measure axial runout at the steering knuckle. In the case of an AWD front ride strut or independent RWD, it may be necessary to mount the dial at the CV joint. Moving the steering knuckle can check lateral runout. For an SLA suspension that has the coil spring over the top arm, the upper joint is loaded. To check the joint, support the upper control arm to unload the joint. If the ball joint has a built-in wear indicator, joint play should be checked with the vehicle on its wheels.

Follower Joint: To check a follower-type joint, the Belleville washer or spring is loaded or compressed to check for axial end play.

For a strut-type suspension, place a jack stand under the cradle to allow the strut to fully extend. Attach the dial indicator clamp to the lower control arm and locate the dial in a vertical position to measure axial runout at the steering knuckle. Place a jack under the ball joint and load the joint by raising the jack. Turn the steering wheel and observe the ball joint to check lateral runout.

For an SLA suspension, the upper control arm can be blocked and the joint can be compressed. Attach a dial indicator to the steering knuckle and locate it in a vertical or parallel position to measure axial runout at the lower control arm. Moving the steering knuckle can check lateral runout.

Tie Rod End Ball Joints: Tie rod end ball joints are more tolerant of wear. Provided an assistant is available to turn the steering wheel of the vehicle in a parked position, the dry-park testing method will indicate excessive wear in most tie rod ends. When a technician is working alone, the tie rod end can be compressed with a pair of water pump pliers while the technician looks for a change in toe angle.

Final Notes

The overall condition of the chassis is important to the safety and performance of a vehicle. In the area of safety, it is a good practice to cover your assets. Be sure the owner is aware of the conditions that could cause their vehicle to be unsafe, and convince them of the importance of proper repairs. If this is not possible, make sure that all safety issues that are not repaired are made apparent in the repair order and a disclaimer is attached.