Affected Vehicle Range: 2004 and later XJ, VIN G00442, and later

A customer may report a concern of a creak or knocking noise coming from the front of the vehicle when driving over uneven ground or turning a corner. The noise may be emanating from the front left-hand side of the vehicle.

Note: Before carrying out this bulletin, refer to Technical Bulletin JTB00008 “Creak from Front Brake Caliper.” If the noise is determined to be coming from the front brake caliper, JTB00008 bulletin should be completed. The vehicle should then be re-evaluated to verify the concern has been rectified. If the concern is rectified after completing JTB00008, this tip (JTB00002 Version 2) should not be carried out.

Note: Welding or lubricating the crush tube to resolve this issue is not authorized by Jaguar Cars.

Should a customer express this concern, verify the source of the noise is coming from the front of the vehicle, and refer to the Repair Procedure detailed in this bulletin to install front crush tube screws.

Repair Procedure:

Install Front Crush Tube Screws

1. Refer to repair information on the removal of the front bumper cover.

2. Remove the sight shield moldings and radiator air defectors.

3. Remove the foam block supporting the A/C pipe to chassis frame for access to the side wall of left-hand crush tube.

Caution: Use a drill bit that has been used only to drill aluminum only to prevent cross contamination with steel.

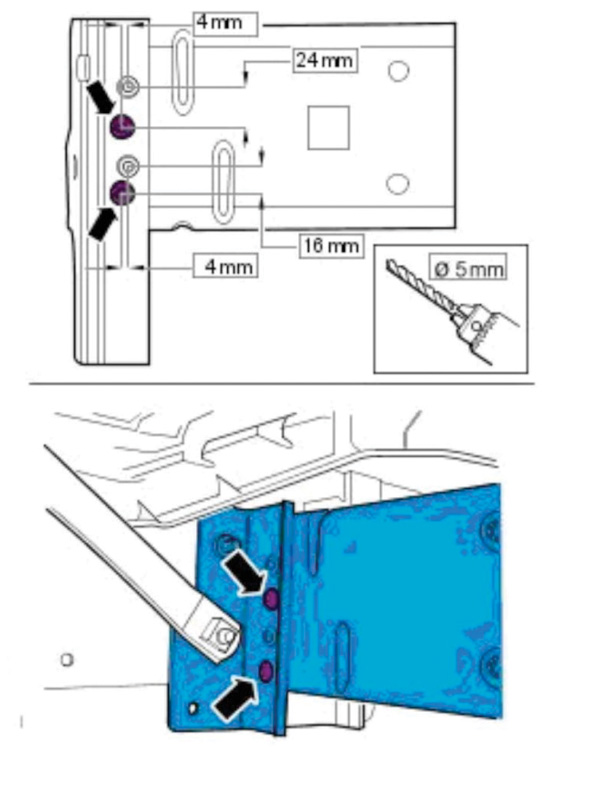

4. Mark and drill two 5 mm (0.200”) holes on both sides of the left-hand crush tube. (see Fig. 1).

5. Apply medium strength thread-locking compound to each new screw.

6. Tighten each screw to 12 Nm (8.85 lbf.-ft.).

7. Drill two 5 mm (0.200”) holes on both sides of the right-hand crush tube.

8. Apply medium strength thread-locking compound to each new screw.

9. Tighten each screw to 12 Nm (8.85 lbf.-ft.).

10. Install the A/C pipe foam block support to the chassis frame.

11. Install the sight shield moldings and radiator air deflectors.

12. Refer to your repair information and install the front bumper cover.

Courtesy of Mitchell 1.