Applicable Models:

1997-’99 CR-V, up to VIN JHLRD_XC_

Parts Information:

Flange Bolt, 10 x 68 mm (4 required): P/N 90172-S04-003

Repair Procedure:

1. Record your customer’s radio station presets.

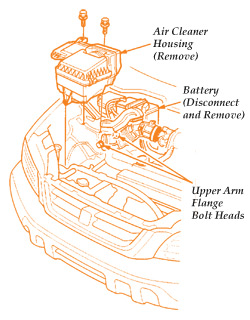

2. Disconnect and remove the battery (see Fig. 1).

3. Raise the vehicle on a hoist, just enough to lift the wheels off the ground.

4. Remove the air cleaner housing (see Fig. 1).

5. Loosen the two flange bolts from the right upper arm. Repeat this step on the left side (see Fig. 1).

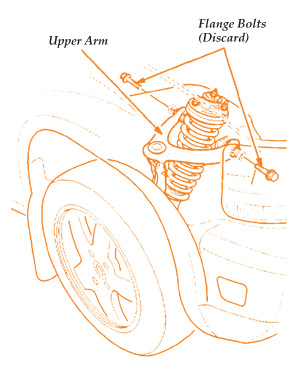

6. While supporting the right front tire with your hand, remove the flange bolts, and ease the upper arm away from the upper arm mount. Discard the flange bolts. Repeat this step on the left side (see Fig. 2).

7. Raise the vehicle about four feet off the ground.

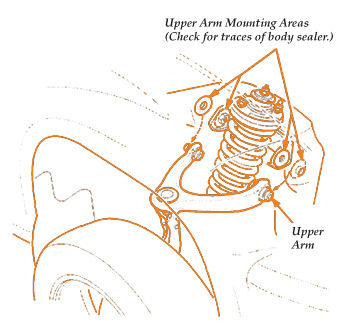

8. From inside the right front wheel well, look for traces of body sealer in the upper arm mounting areas. If any body sealer is found, remove it with a gasket scraper. Repeat this step on the left side (see Fig. 3).

Note: Be careful not to scratch the body finish. If you do, repair the area with touch-up paint.

9. Lower the vehicle until the wheels are just off the ground.

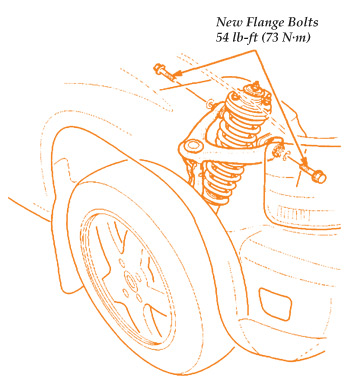

10. Reinstall the right upper arm, and secure it with two new flange bolts (see Parts Information). Repeat this step on the left side (see Fig. 4).

Note: When installing the new flange bolts, you may need to move the tire slightly with your hand to align the bolt holes.

11. Lower the vehicle to the ground, and then torque the four new flange bolts to 54 lb.-ft. (73 Nm).

12. Reinstall the air cleaner housing. Torque the two flange bolts to 7.2 lb.-ft. (9.8 Nm).

13. Reinstall the battery.

14. Reset the radio station presets, and set the clock.

15. Test-drive the vehicle over bumps to make sure the noise is gone.

Written by Dennis Shortino, ALLDATA Editor and Jeff Webster, ALLDATA Technical writer.