By Eric Seifert

Automotive Technical Editor

Recently, a customer encountered trouble climbing a grade in his 2005 Infiniti QX56 while towing his boat. He called to express his concerns about the Infiniti’s sudden lack of power.

When accelerating with wide open throttle (WOT), the engine power is reduced.

Actions

1. Check fuel pressure during a transmission Stall Test (see Service Procedure).

2. If fuel pressure test is NG, replace the fuel pump.

Note: Low fuel pressure may cause DTCs to be detected. If you have DTCs with this incident, first replace the fuel pump and then recheck the DTC diagnosis.

Important: The purpose of these “Actions” is to give you a quick idea of the work you will be performing. You must closely follow the entire Service Procedure as it contains information that is essential to

successfully completing this repair.

Applicable Vehicles: 2004-’07 QX56 (JA60); 2004-’06 all VINs; and 2007-Built before 5N3M08(**)7N 806064 (Built before Feb. 22, 2007)

Applicable Vehicles: 2004-’07 QX56 (JA60); 2004-’06 all VINs; and 2007-Built before 5N3M08(**)7N 806064 (Built before Feb. 22, 2007)

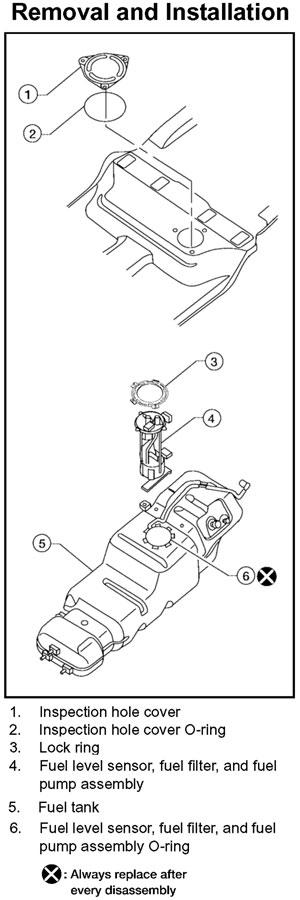

Parts Information: A new fuel pump, P/N 17040-7S20A (2004-’06) or 17040-ZE00B (2007), along with a fuel pump O-ring, 17342-7S000, may be required to complete the repair. See Figure 1.

Service Procedure

1. Connect a fuel pressure gauge to the engine (special tool kit J-44321 or equivalent).

• Follow all instructions under “Fuel Pressure” in ALLDATA for connecting the fuel pressure gauge.

2. Look at the fuel pressure while performing a transmission “Stall Test.”

• The Stall Test 10-minute warm-up is not needed for this Service Procedure.

• Follow all other instructions for performing the Stall Test under Automatic Transmission Testing in ALLDATA.

Caution: Do not hold down the accelerator pedal for more than five seconds while performing the Stall Test.

• Fuel pressure is NG if it drops below 45 psi during the Stall Test.

– If the fuel pressure is OK, this bulletin does not apply.

– If the fuel pressure is NG, go to step 3.

3. Replace the fuel pump.

• Follow all instructions under Fuel Pump in ALLDATA.

• Use the fuel pump listed in the Parts Information.

• Make sure to use a new fuel pump O-ring seal.

4. Test-drive the vehicle; make sure the incident is fixed.

Note:

• Low fuel pressure may cause DTCs to be detected. If you have DTCs with this incident; first replace the fuel pump and then recheck the DTC diagnosis.

• DTC diagnosis and repair is not covered by this procedure.

Written by ALLDATA Technical Editor, Eric Seifert, an ASE certified Master Technician and Engine Machinist, with 20 years of independent shop and parts store experience.

Courtesy of ALLDATA.

For additional information, visit www.alldata.com.