Ford Vehicles:

• 2003-2005 Excursion

• 2003-2007 F-Super Duty

• 2004-2006 E-Series

Issue:

Some 6.0L vehicles may exhibit a misfire, lack of power, buck/jerk, excessive smoke or crank/no start. There are several potential causes for these symptoms.

Action:

If normal diagnostics lead to an injector concern, use the following diagnostics to confirm the cause of injector failure and/or to rule out other conditions which may cause the same symptoms as a failed injector.

Note: If diagnosing a lack of power condition, be aware 2005 and forward model year vehicles have a “forced limited power” strategy which limits injection control pressure (ICP) when the fuel level in the tank gets very low (well after the low fuel light comes on). When this occurs, diagnostic trouble code (DTC) P115A will be stored in the powertrain control module (PCM).

Low or Negative Fuel PressureInternal injector damage can be caused by lack of fuel system supply pressure. Restricted fuel filters and/or fuel line(s), or an inoperative fuel pump can create a low or negative fuel supply pressure. Low or negative pressures may hinder the return stroke of the injector intensifier plunger to its rest position, leading to internal injector damage.

To diagnose for low or negative fuel pressure and to confirm if any injectors have been damaged:

- Perform standard diagnostic procedures including verification of supply fuel pressure while the symptom is evident, or during a 0-50 mph (o-80 km/h) wide open throttle (WOT) acceleration (full load).

- Repair causes for low pressure on the supply side of the fuel system.

- Diagnose for failed injector(s) only after rectifying fuel supply pressure.

- Recheck the fuel pressure after repairs by repeating the 0-50 mph (0-80 km/h) WOT acceleration (full load) test.

Combustion Gas Entering the Fuel System

Inert combustion gas in an injector can cause a random misfire in one or many cylinders. Combustion gas may leak past the injector’s needle and seat, or the copper combustion seal. Once the combustion gas enters the fuel rail in the cylinder head, it then distributes to other injectors, typically on the same bank.

To diagnose for combustion gas entering the fuel system:

- Remove outlet fuel lines from the fuel filter housing on top of engine.

- Install a balloon over each fuel line with a zip tie.

- Disable the fuel pump and fuel injection control module (FICM) relays.

- Crank engine and watch for compression pulses in the balloon.

- For each line where compression pulses are evident, remove all but one of the glow plugs from the affected cylinder head(s).

- Crank engine and watch again for compression pulses.

- Remove the glow plug and transfer it to the next cylinder in the head and repeat Step 6.

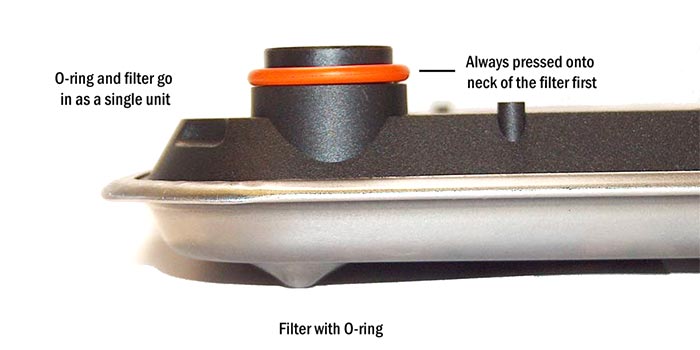

- For each cylinder where compression pulses are evident, remove injector(s) and inspect copper gasket and lower O-ring. Replace if necessary. If gasket(s) and O-ring(s) are OK, replace injector(s). Retest to confirm repair.

Note: Any time an injector clamp is loosened and/or injector removed, the copper gasket and O-rings must be replaced. They can never be reused.

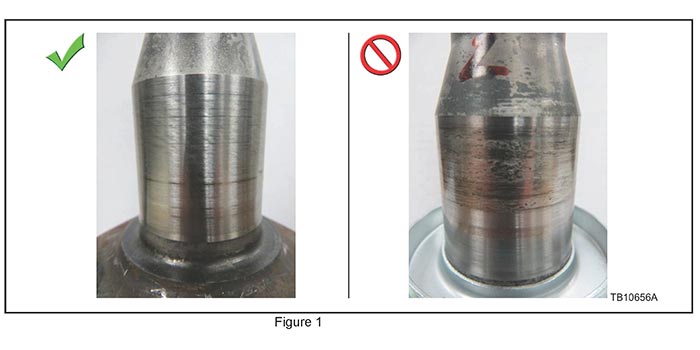

Copper Gasket Inspection

- Remove the suspect injector and inspect for a missing or damaged copper washer. Review repair history as a missing injector copper washer is most likely caused by improper injector torque at a prior repair for injector replacement.

- Using an injector that is not damaged, install a new copper washer and install the injector per Workshop Manual Procedure 303-04C and tighten to 24 ft-lb (33 Nm). Note: Super Duty vehicles built 1/16/2006 and later, and Econoline vehicles built 1/23/2006 and later, injector torque is 26 ft-lb (35 NM) and utilizes a T-45 torx bit.

- Remove injector and inspect copper washer crush pattern. An even circular crush pattern should be visible on sealing surface of copper washer. If the crush pattern is not visible, or not a complete even circular pattern (C shape pattern), the copper injector washer can leak or fail prematurely.

- Additional possible causes of damage to the copper washer could be:

B. Hold down bolt stretched from improper torque.

C. Damaged injector.

D. Damaged injector cup.

Note: After replacement of any faulty components — with new copper washer, repeat injector copper washer crush test to verify correct crush pattern.

Note: Any time an injector clamp is loosened and/or injector removed, the copper gasket and O-rings must be replaced. They can never be reused.

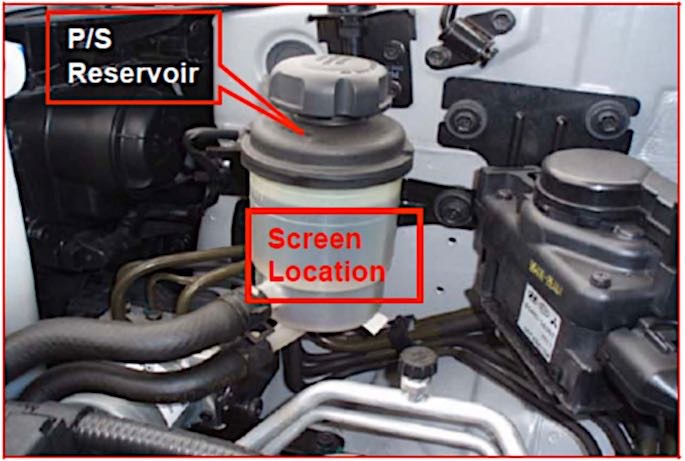

Erratic High Pressure Oil Supply

Erratic supply of high pressure oil to injectors may cause a rough running engine. High pressure oil flow can be disrupted by faulty check valve(s) or a faulty Injector Pressure Regulator (IPR) valve.

To diagnose, first perform a slow neutral run up in park/neutral. If the engine runs rough between 1200 and 2300 rpm, proceed to Check Valve Diagnosis. If the engine runes rough between 2000 and 4000 rpm, perform PC/ED pinpoint test Q. If the engine continues to run rough between 3000 and 4000 rpm after having validated the ICP sensor and connector, then replace the IPR valve.

Check Valve Diagnosis

- To isolate the bank with the faulty check valve, disconnect all of the injector connectors on one bank.

- Perform a Power Balance test. Engine misfires should be constant on the four disconnected cylinders and the operational cylinders should be contributing evenly.

- Repeat Steps 1 and 2 on the opposite bank.

- If the operating contribution is erratic on one bank, replace the check valve on that bank.

Parts Information

Part Number — Part Name

3C3Z-9E527-AE — Injector 2003-2004

4C3Z-9E527-AA — Injector 2004-current

3C3Z-9229-AA — O-ring and gasket

3C3Z9324-AA — Check valve 2003-2004

5C3Z-9A332-A — Check valve 2004-current

3C3Z-9C968-AA — IPR valve

For additional information, visit www.mitchell1.com.

Technical service bulletin courtesy of Mitchell 1.