Vehicles:

Vehicles:

- 2002 Civic Si — All;

- 2003 Civic Si — from VIN SHHEP3…3U400001 thru SHHEP3…3U406119; and

- 2003 CR-V — from VIN SHSRD6…3U100001 thru SHSRD6…3U106587; from VIN SHSRD7…3U100001 thru SHSRD7…3U141932.

Symptom:

Knocking coming from the front suspension while driving over a bumpy road.

Probable Cause:

The damper shaft nut isn’t tight enough.

Corrective Action:

Loosen and retorque the damper shaft nut to the appropriate torque specification.

Diagnosis:

Test drive the vehicle over a rough road while turning left or right. Note any noise and the side(s) it comes from.

Repair Procedure:

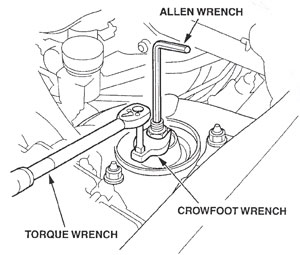

- Hold the damper shaft with a 6 mm hex (Allen) wrench, and loosen the damper nut 1/2 turn with a 17 mm crowfoot and ratchet. See Figure 1.

- Hold the damper shaft with a 6 mm hex (Allen) wrench, and use a torque wrench with a 17 mm crowfoot to torque the damper shaft nut to 49 Nm (36 lb-ft).

- Repeat steps 1 and 2 for the other side, if necessary.

- Test drive the vehicle to confirm that the noise is gone.

Technical service bulletin courtesy of Mitchell 1.

For additional information, visit www.mitchell1.com.