A hybrid vehicle is a different animal than many of us are used to seeing. After all, if the engine of a typical vehicle stalled out at a traffic light, the driver of that vehicle would know something was wrong with it. If that same vehicle still drove with the engine off, then that would mean they were probably going down hill. But, in the hybrid world, that is all normal. Systems around the vehicle are impacted by two key features:

- The engine does not run at all times.

- The high-voltage batteries need to be recharged on the drive.

The control side of a hybrid brake system exhibits differences when compared to its conventional cousins in order to accommodate these conditions.

REGENERATIVE BRAKING

We all heard this one in science class: “Energy cannot be created or destroyed. It can only be transformed from one form to another.” In the case of conventional friction brakes, energy of motion (kinetic energy) is being transformed into heat energy, via friction, and then dissipated into the air.

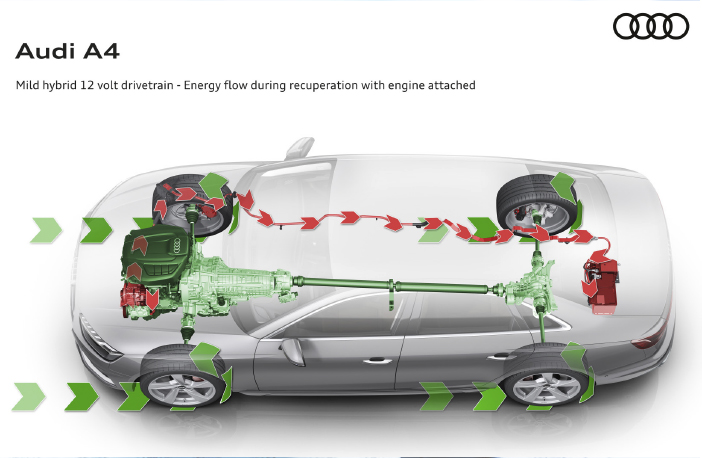

A hybrid vehicle recharges its high-voltage battery through the use of regenerative braking. With regenerative braking, instead of just wasting that energy by releasing it into the air, the vehicle captures it and saves it in a box in the back of the car as stored energy. Later, that stored energy will be converted back into kinetic energy and poured back into the operation of the car.

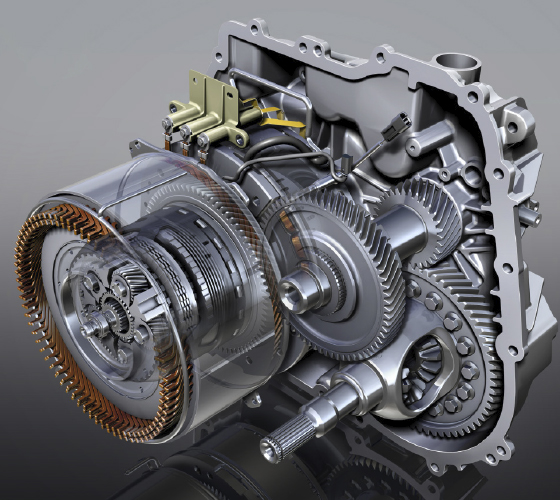

Regenerative braking is the hybrid’s first choice for braking. So, basically, on a hybrid vehicle, the brake pedal acts more as an interface for the ABS module than as a request for braking. The brake pedal and ABS module pressure sensors “tell” the modules of the hybrid system that a request for braking has been made and how much braking is desired — the driver’s pedal efforts are calculated by the modules in order to produce the correct pedal feel and stopping power. The modules that control the hybrid system then apply regenerative braking via the traction motor inside the transmission, as needed. More regenerative braking increases the amount of electrical charge generated for the hybrid battery, at the same time it produces more drag to slow down the vehicle. Of course, at a stop or near-stop, the friction is applied to stop the vehicle from rolling. Some hybrid systems apply the hydraulic brakes at lower speeds.

During many light-braking events, the rear friction brakes will be lightly applied and the front may not be applied at all until the vehicle is at a stop or near-stop. For this reason, it is normal for a hybrid to wear the rear brake pads two and three times faster than the front pads.

On most hybrids, the pressure generated for the calipers is not, under normal conditions, the direct result of the driver’s foot pedal efforts. The pedal-generated pressure is used to stimulate a pressure sensor in the system that makes up the brake request. Normally, the fluid pressure for the wheel hydraulics is generated by the pump and/or accumulator in the ABS HCU or a stroke simulator, and is regulated by the teamed efforts of the ABS and the PCM’s logic.

The higher the request for braking, the system electronically calculates and decides how to apply friction and regenerative braking to meet the demand. From feather-light braking to a panic stop, all brake applications are electronically calculated and delivered from a normally operating electrohydraulic brake system.

In the event that the ABS HCU can’t function well enough to build pressure, the driver’s pedal pressure will directly provide the hydraulic pressure for the calipers. There are valves inside the HCU that allow direct passage from the pedal feel simulator, through the HCU and to the wheels. This is called “manual mode.” In manual mode, there will be no boost so the driver will have a very hard/stiff brake pedal. The driver will need so much braking effort in this situation that it may prompt them to tow the vehicle for fear of having no ability to stop at all. Complaints of “no brakes” or “barely stops” is often how customers will describe a brake system that has entered manual mode (fail-safe mode).

CUSTOMER COMPLAINTS

The two-mode hybrid system has a unique brake pedal because the hydraulic system is not the lone provider of vehicle deceleration. How the system blends these forces can cause a customer to notice the changes and become concerned.

Over several braking events, the customer may perceive that he or she is applying a consistent brake force, yet the vehicle may decelerate at slightly different rates. This is a normal operating characteristic. The driver may think it is the same type of stop, but to the system, a little extra speed or pressure can change braking performance or the blending of the brake mechanisms.

Another common complaint for used hybrids is noise and pedal feel. Most two-mode hybrid vehicles, like the Prius, GM Two-Mode and Ford Escape, use a braking system that employs a high-speed electric motor/pump. Pump operation sometimes can be felt in the brake pedal as the system builds pressure. This is most noticeable to customers who start the vehicle with their foot on the brake pedal. Also, the noise can be more noticeable if the engine is off and the customer is braking.