Overall, the 2002-2010 Jeep Liberty is an easy vehicle to align, but you do have to pay attention during the initial inspection. Instead of having to install offset ball joints and shims to adjust camber and caster in the 2002-2010 Jeep Liberty, the adjustments are performed with the cam bolts in the lower control arms. The rear is not adjustable.

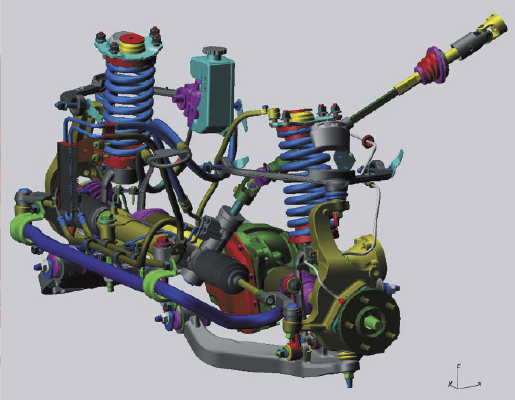

Front Suspension

The Liberty’s front suspension uses upper and lower control arms. The replacement of the upper control arms can be tedious and require the removal of the battery tray, power distribution center and other components to get at the passenger-side upper control arm.

The control arms are robust, but the stock ball joints proved to be this vehicle’s weak link early in its life. Jeep issued five recalls concerning ball joint failure for various 2002-2006 models. Most of the recall documents cite corrosion of the joint as the cause of the failure. The culprit was water intrusion, which was often blamed on poor sealing of the boot and/or a missing heat shield on early models that allowed the boot to be degraded.

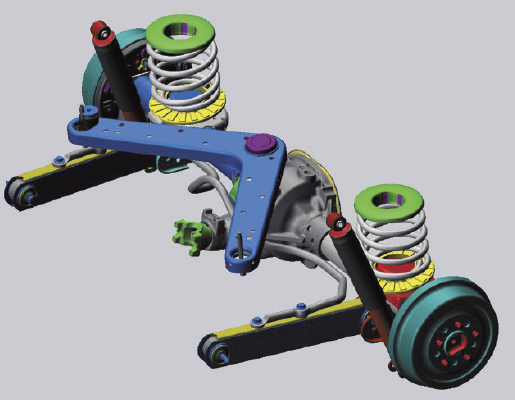

Rear Suspension

The rear suspension on the Liberty is non-adjustable, and the only specification is for the thrust angle. When taking the initial readings, pay attention to the thrust angle. If the thrust angle is greater than specifications, inspect the rear suspension for damage or worn bushings.

On 2002-2007 models, the single upper control link looks like a boomerang and utilizes a single ball joint mounted to the axle. There should be no play in this joint.

On 2008 and up KK models, Jeep changed the rear suspension to a four-link setup with a lateral link.

Ride Height

Front ride height is defined by the vertical distance between the spindle and the rear pivot point of the front lower control arm bolt. When the car rolls off the line, the two points should parallel, -/+10 mm.

Rear ride height is defined by the vertical distance between the top of the lower spring seat strike surface and the bottom of the jounce cup (true metal-to-metal jounce travel). This is to be measured vertically inside the coil from the point intersecting the inboard edge and the fore/aft center of the jounce cup down to the strike surface. The distance should be 97 mm -/+ 10 mm.

Adjustments

Jeep has gone back and forth on whether or not they should install cams on the lower control arms, but every Liberty has the fences for the cams. Before you quote the price of the alignment, make sure to check for the cams.

Camber and caster angle adjustments involve changing the position of the lower suspension arm cam bolts. Moving the rear position of the cam bolt in or out will change the caster angle significantly and camber angle only slightly. To increase positive caster angle, move the rear position of the cam bolt outward (from the engine). Move the front of the cam bolt inward (toward the engine) slightly until the original camber angle is obtained.

To adjust the camber, move both of the cam bolts together. This will change the camber angle significantly and caster angle slightly. The torque spec for the lower control arm bolts is 125 ft/lbs..