With more than half a million made and almost 65,000 police interceptors in use, the sixth-generation Ford Taurus is a vehicle that will roll into your alignment bay sooner or later.

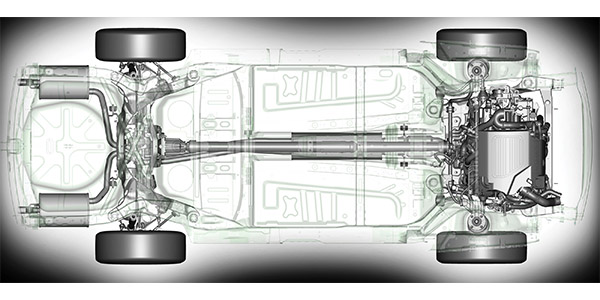

The suspension is typical Ford. The front suspension uses a MacPherson strut and a lower control arm with a large bushing at the rear. The rear suspension is a multi-link arrangement that differs little between the front-wheel-drive and AWD models.

Steering

The Taurus uses electric power steering. The system is very robust, but the weak point is the wiring. The connectors, modules, and wires reside low in the engine bay and are subjected to water, debris and heat from the engine. Ford has issued a general service bulletin and offers an updated harnesses to correct the problem.

The steering angle is computed with position sensors on the motor, angle sensor on the column and data from the ABS module. When the car is first driven, it goes through a self-calibration cycle, the pieces of data are compared, and if the discrepancies are too large, a code will be set, and the steering will go into a safe mode.

Some Taurus models equipped with electric power steering will have active park assist. The active park assist system is controlled by the Parking Aid Module which can detect a parking space and steer the vehicle into the space by sending commands to the electric power steering system.

Front Suspension Adjustments

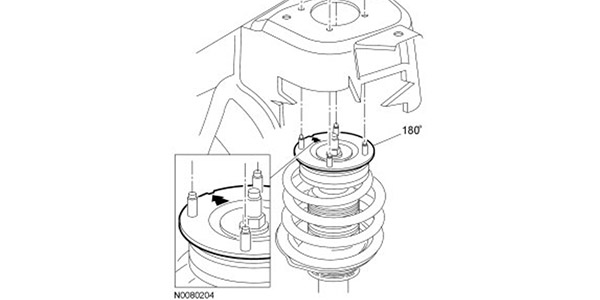

Front caster is not adjustable on the Taurus. The camber is factory adjustable by rotating the upper strut mount. By turning the upper strut mount 180 degrees, it can give .5 degrees of positive camber. If the camber is out of specification, look at other issues with control arm bushings and the ride height. The tell-tale sign of a control bushing problem is a caster angle also out of specifications.

Rear Suspension Adjustments

Only the rear camber and toe are adjustable. Rear camber is adjustable from the factory. The upper arm is slotted where it connects to the knuckle. At the factory, the knuckle is pushed inboard for maximum negative camber. If additional camber adjustment is needed, cam bolts are available.

TPMS Relearn

- Turn the ignition to the OFF position.

- Turn the ignition to the RUN position three times, ending in the RUN position. Do not wait more than two minutes between key cycles.

- Press and hold the brake pedal.

- Turn the ignition switch to the OFF position.

- Turn the ignition switch to the RUN position three times, ending in the RUN position. Do not wait more than two minutes between each key cycle.

- When the message center displays “TRAIN LEFT FRONT TIRE,” place the magnet on the valve stem of the LF tire pressure sensor. The horn will sound briefly to indicate that the tire pressure sensor has been recognized by the TPMS module.

- Within two minutes after the horn sounds, place the magnet on the valve stem of the RF tire pressure sensor.

If the TPMS module does not recognize any one of the five tire pressure sensors during the tire training procedure, the horn will sound twice and the message center will display “TIRE TRAINING MODE INCOMPLETE” and the procedure must be repeated. - Repeat Step 7 for the RR, LR and spare tire.

When the tire training procedure is complete, the horn will sound twice and the message center will display “TIRE TRAINING MODE COMPLETE.”

SIDEBAR

Ford Fasteners

If you have looked at any service information from Ford in the past decade, you will notice an arrow and trash can on some of the diagrams. Also, in the warnings that say:

NOTICE: Suspension fasteners are critical parts because they affect the performance of vital components and systems and their failure may result in significant service expense. New parts must be installed with the same part numbers or equivalent part if replacement is necessary.

When you look at the fastener on the vehicle, it is not a torque-to-yield fastener or anything special. The bolt may have thread-locking compound, or the nut might have a nyloc insert.

It is a no brainer to clean the bolt and apply fresh thread-locking compound. Nyloc fasteners can be more controversial and confusing. Some automotive authorities say that nyloc fasteners can be reused and still not lose their compressive force. But in the aircraft industry, reusing nylocs is not allowed.

The best rule of thumb to use is to use your best judgment and inspect the fastener. If a bolt looks stretched, replace it. If the nyloc has been damaged by heat or physical damage, replace it.