The dual-clutch transmission takes the best parts of a manual transmission and combines them with the best features of an automatic. This combo produces a drivetrain that has the efficiency of a manual transmission, but the ease of use of an automatic. Compared to automatic transmissions, one manufacturer claims a 5–10% reduction in fuel consumption from just this one feature.

Internally, the dual-clutch transmission is more efficient than an automatic because there are fewer moving parts. Also, with an automatic transmission, the engine has to drive a pump and some energy is lost in the torque converter and clutch packs.

Most vehicle owners with dual-clutch transmissions think they are driving an automatic. However, the combo makes for a new service and diagnostic challenge for technicians. These transmissions can be found on entry-level compacts and even some light-duty pickups.

How Does It Work?

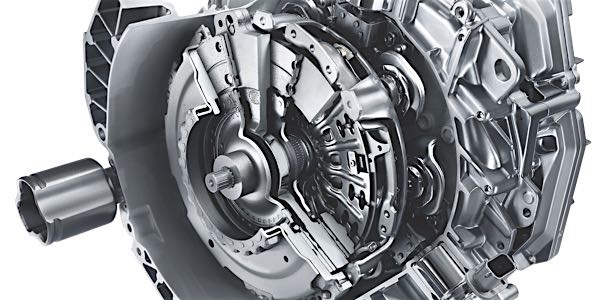

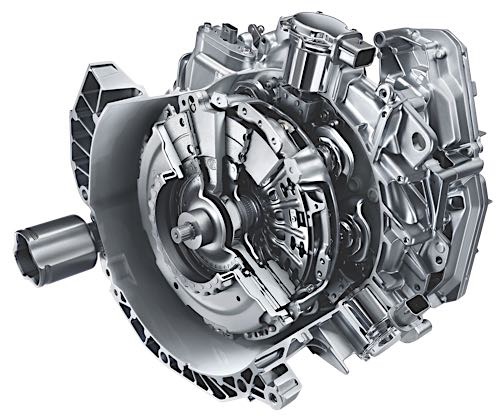

Dual-clutch transmissions are like having two manual transmissions shifting together. However, the stick shift is gone. In its place are shift forks actuated by hydraulic or electric solenoids. And, there is no clutch pedal. Engagement of the clutch is achieved by the computer-controlled actuators.

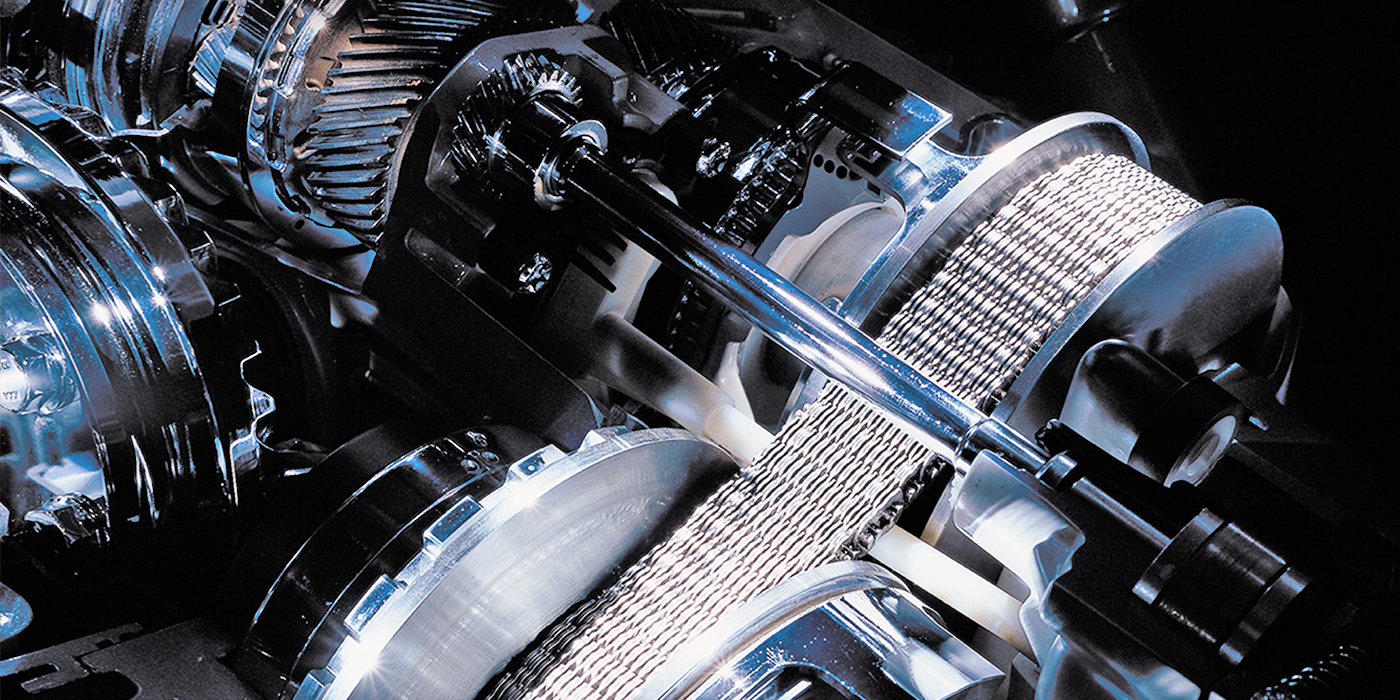

The input shafts connect to what could be called countershafts that run parallel to each other. One shaft can have the odd-numbered gears, while the other has the even gears. Some manufacturers call each shaft a “sub transmission.” The shafts connect to the output shaft. While one gear on a shaft is driving the wheels, the next anticipated gear is engaged and readied on the opposite shaft while its clutch is disengaged.

Service Opportunities

The clutches in dual-clutch transmissions wear and will eventually need replacement. Most units coming to market feature the clutches packaged together. On the majority of dual-clutch transmissions, it is impossible to replace only the clutch discs.

These vehicles can still suffer the same problems with oil contamination from leaking seals on the transmission or engine. The most common sign of a contaminated clutch is a shudder in the drivetrain. The next most common problem involves the hydraulic or electric controllers. Some dual-clutch transmissions have valve bodies that are mounted in the pan or in the case. Some transmission manufacturers call this the “mechatronic” part of the transmission.

These modules or solenoids are not unlike current automatic transmission valve bodies — and represent a considerable service opportunity. Fluid maintenance is also key in keeping a dual-clutch transmission operating as designed. Most current dual-clutch transmissions hold four to nine liters of fluid. Some even have filters to capture metal debris. The Ford Focus has a 150,000-mile service recommendation for normal conditions.

Volkswagen also recommends a 150,000-mile service interval, but lowers it to 30,000 miles if the vehicle is used for towing. Some manufacturers say that the fluid will last the life of the transmission, which is code for “until the warranty runs out.“ The greatest potential service opportunity for dual-clutch transmissions is reflashing and reprogramming.

Automakers are constantly improving the software that engages the clutch and shifts the gears. The new calibrations can improve shift quality on clutches that are worn.