The following diagnosis might be helpful if the vehicle exhibits the symptom(s) described in this bulletin.

The following diagnosis might be helpful if the vehicle exhibits the symptom(s) described in this bulletin.

MODELS

2003-2011 Saab 9-3 Sedan

2004-2011 Saab 9-3 Convertible

2006-2011 Saab 9-3 Combi

CONDITION/CONCERN

A customer may complain of a snapping or popping noise on turns from the front suspension. This typically occurs on sharp turns such as a parking lot maneuver. Have the technician duplicate the concern to verify the noise is coming from the front suspension.

RECOMMENDATION/INSTRUCTIONS

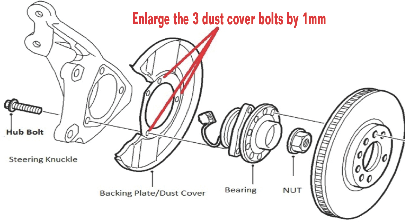

After the technician has duplicated the concern to verify the noise is coming from the front suspension, make sure are all components are torqued to specs. Also, a number of wheel bearings have been replaced with the thinking that was the root cause. In fact, the brake backing plates are popping over the mounting bolts when the suspension is flexed and the wheel is turned. To remove the backing plate, follow WIS path 9440/Front suspension/Adjustment-Replacement/Wheel Hub Front.

NOTE: Do not replace wheel bearing or hub.

After removal of the backing plate, have tech enlarge the mounting holes in the plate enough to ensure they will not bind or contact the mounting bolt. (1 mm is a good rule of thumb). Reinstall per WIS path 9440/Front suspension/Adjustment-Replacement/Wheel Hub Front – carefully providing necessary clearance between the backing plate and its components.

Courtesy Saab Automobile Parts North America

www.saabparts.com