Vehicles affected: 2007-’08 Ford Escape and Mercury Mariner

Some 2007-’08 Escape and Mariner vehicles equipped with a CD4E transmission may experience a loss of second and fourth gear.

Service Procedure

1. Check the transmission fluid condition. Refer to Workshop Manual (WSM), Section 307-01A.

Does the fluid condition pass evaluation?

a. No – this article does not apply, refer to WSM, Section 307-01A for normal diagnostics.

b. Yes – proceed to Step 2.

2. Remove the automatic transaxle.

3. Remove the torque converter and pump shaft from the transmission.

4. Remove the turbine speed sensor (TSS) from the pump; discard the TSS O-ring seal.

5. Position the transaxle so the pump assembly is facing upward.

6. Remove the servo cover retaining ring, servo cover, servo piston and return spring.

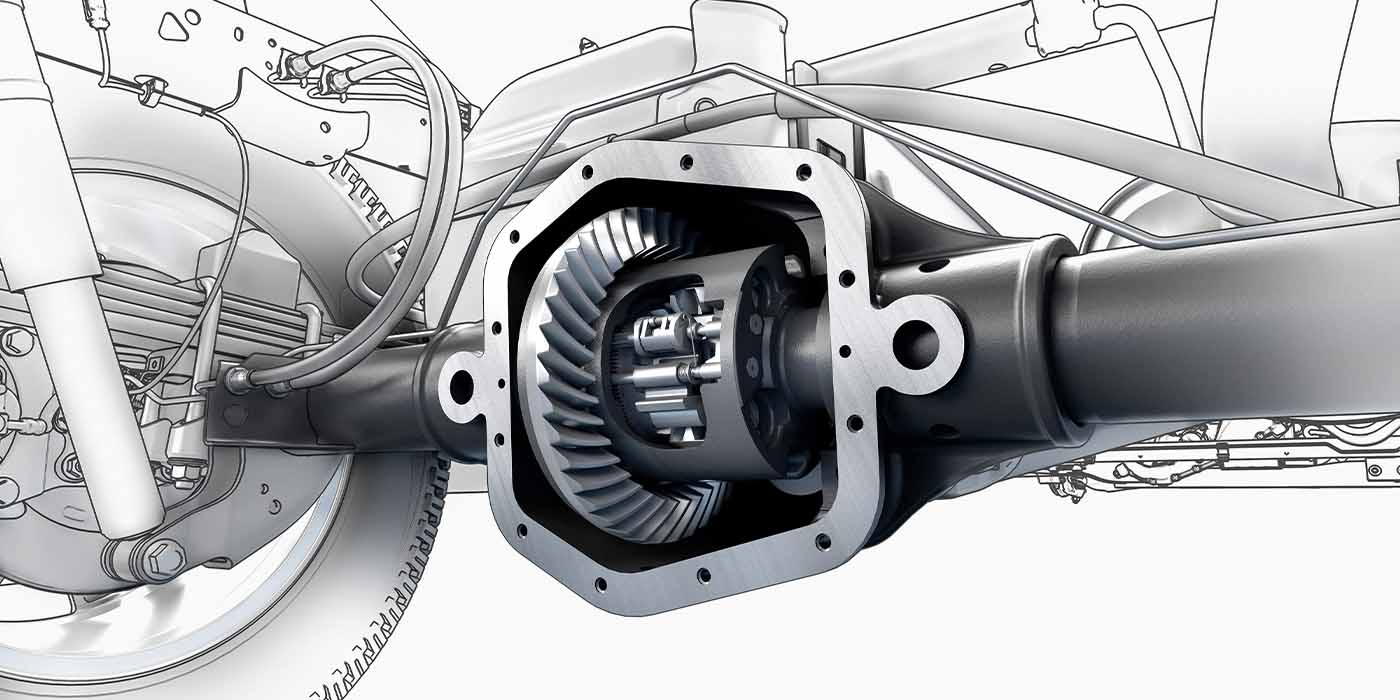

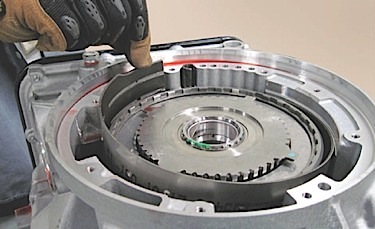

7. Remove the pump assembly while holding the rotating parts in place using a screwdriver inserted through the turbine speed sensor hole in the pump while removing the pump assembly. See Figure 1.

8. Remove the intermediate and overdrive band assembly from the case. Be sure to get all pieces and make sure no contamination is left inside the transmission. See Figure 2.

– Choose the correct band for application from

the kit:

– four-cylinder engines require light-colored friction material; and

– six-cylinder engines require dark-colored friction material.

9. Install the intermediate and overdrive band assembly into the case.

10. Install the #1 pump support thrust bearing onto the pump support with petroleum jelly.

11. Install the pump assembly into the case with a new pump separator plate gasket and outer pump body O-ring.

12. Measure servo travel; select and install the correct length servo rod assembly.

13. Install a new servo cover and retaining ring.

14. Install a drain plug using thread sealer on the threads, torque to 25 Nm (18 lb.-ft.).

15. Install a new O-ring on the TSS sensor and install the sensor into the pump.

16. Position the transmission top side up.

17. Install the pump driveshaft and torque converter.

18. Install the automatic transaxle.

Courtesy of Mitchell 1.