Oxygen Sensor Heater Codes

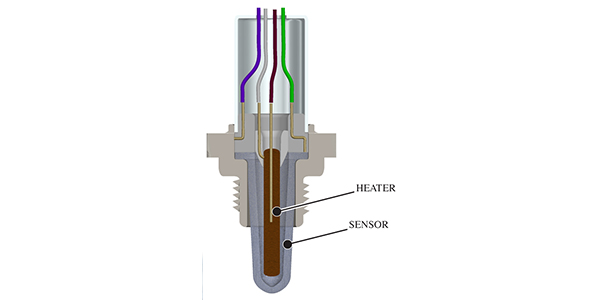

An oxygen sensor code related to the heater circuit can be difficult to cure.

One of the most difficult problems to cure is an oxygen sensor code related to the heater circuit. If you decide to just put in a new sensor and clear the codes, there is a chance the code will come back because the malfunction in the circuit is not in the oxygen sensor.

Catalytic Converter Replacement

Converters must be certified and labeled with the correct codes that are stamped into the shell.

Determining Catalytic Converter Efficiency

Tiny details can limit the life of a catalytic converter.

Stainless Steel Did Not Kill The Exhaust Repair

Direct fit parts can be used to make an effective repair quickly.

Resetting Emissions Monitors After Converter Replacement

Here are the 10 commandments of a catalytic converter replacement handed down from the EPA.

Other Posts

Tesla Wheel Bearing Replacement

The process of replacing the hub unit on a Tesla is the same as many cars and light trucks.

Brake Pad Edge Codes – What Can They Tell You?

The edge code is a language written by engineers, federal entities and industry associations.

Brake Problems

Reducing brake drag on late-model vehicles is not accomplished by a single component; it takes a system.

The Real Cost of Installing Cheap Brake Pads

The brake repair market is starting to become dominated by a “good enough” mentality.