Timing chain replacement was once a seldom performed job on import vehicles. Usually, the body rusted out or other mechanical problems sent the vehicle to the junkyard long before the chain would stretch or break.

Now, with vehicles lasting longer and accumulating more miles, timing chain replacement on some models is becoming a much more common occurrence.

What’s to blame? Some say it is a mileage and longevity problem. Some say it is because chains have become longer and have more links to wear out. No matter the reason, your shop has probably seen an uptick in this type of service.

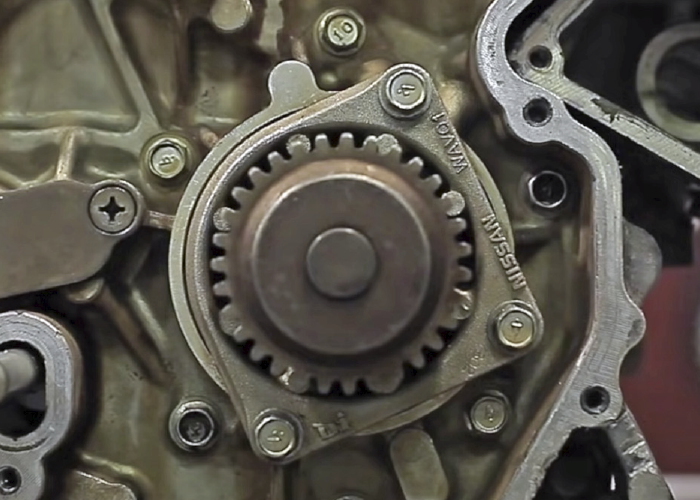

The aluminum DOHC Nissan VQ V6 requires a decent amount of disassembly to service the timing chains. The valve covers, front cover and other components need to be removed. When replacing the timing chain, do the complete job and replace the tensioner, guides and, in some cases, the sprockets. On higher mileage engines, replacement of the variable valve timing phasers is recommended. But, on all jobs, the water pump should be replaced.

Tensioners

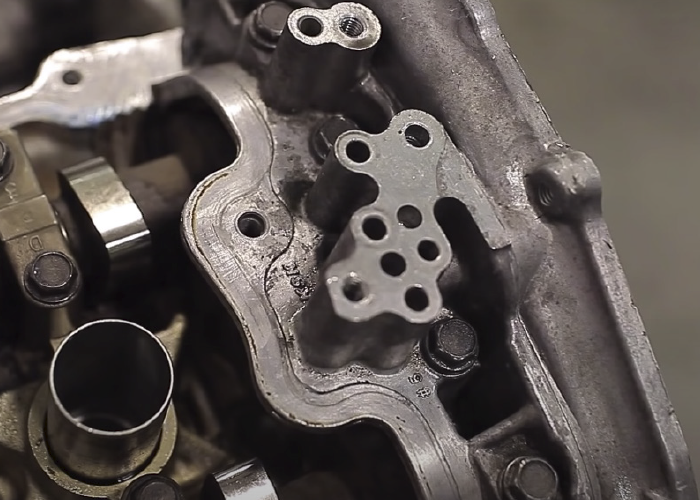

The VQ V6 has three oil-powered chain tensioners. The main chain has a tensioner and two secondary chain tensioners. When replacing the main chain tensioner, make sure the mating surfaces are clean and free of damage and debris. The secondary chain tensioners require the removal of the intermediate covers and camshaft bearing caps.

Replace the gaskets and the sealants that go into the grooves on the caps and covers. Not getting this step correct can lead to internal leaks that can drain the tensioner and phaser. Leaks can cause noise during startup as oil refills the tensioner and phaser.

On engines with variable valve timing, you will have to remove the oil control solenoids. Always use a new gasket and seals on the valves.

The condition of the guides can also cause timing system instability during startup. Lack of oil can cause the guides to melt. Also, if the tensioner is collapsed during startup, the chain whip can cause the guide to break.

Chain

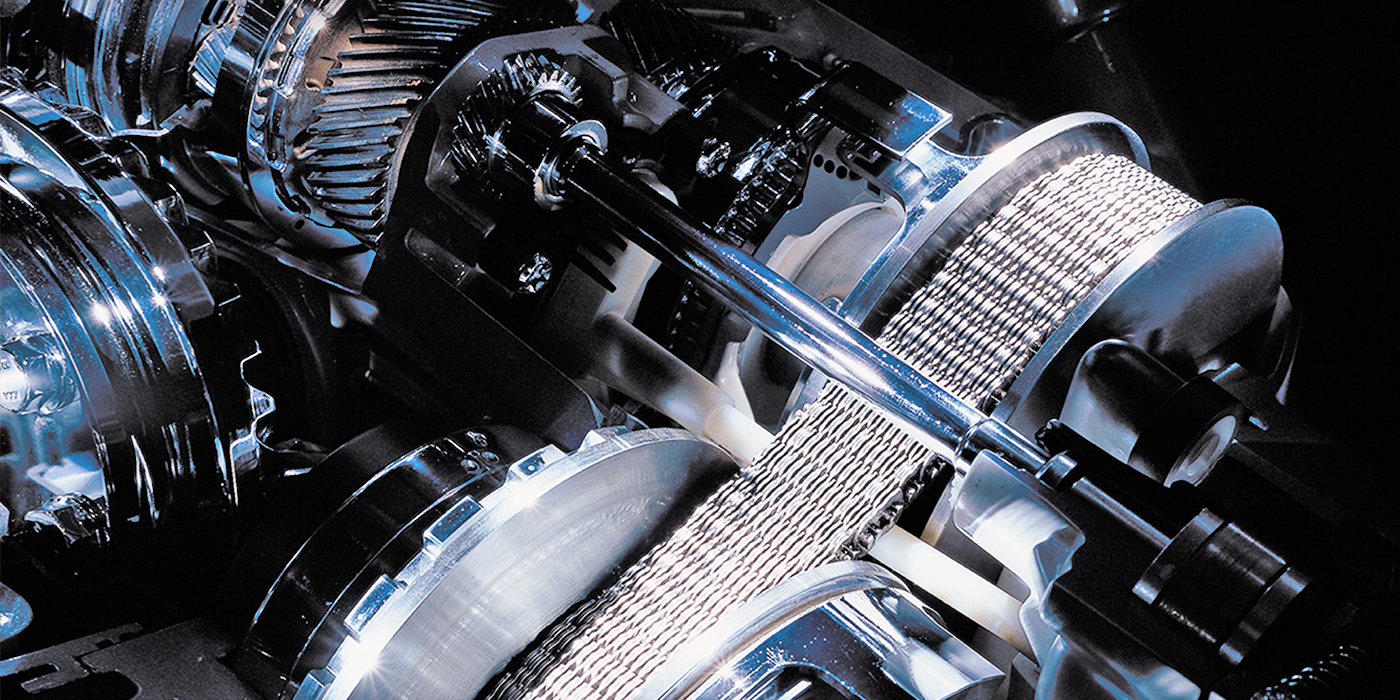

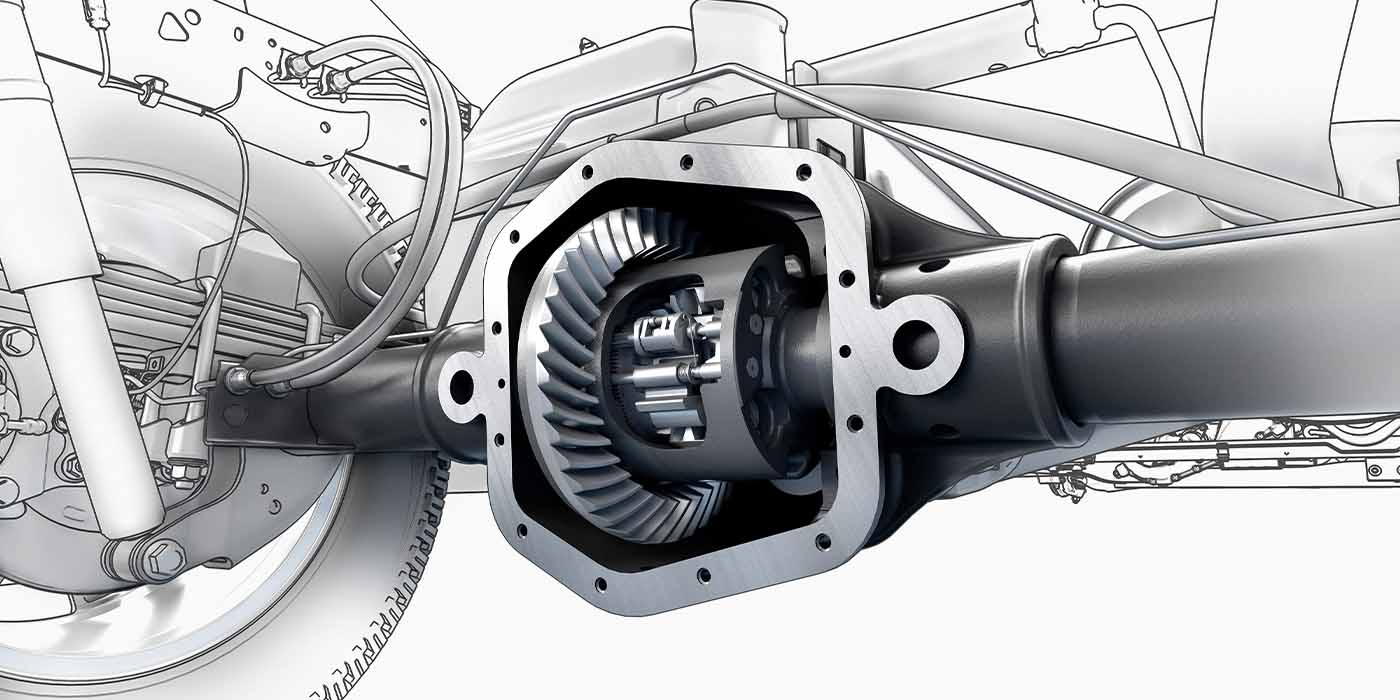

The main timing chain uses an inverted-tooth design. It has interlaced links held together with pins. Instead of a roller making contact with the teeth of the sprocket, the links make contact. Inverted tooth chains are typically quieter than roller-style chains.

The shape of the links of an inverted- tooth timing chain is specific to the sprockets. The Nissan links in this type of chain engage in specific areas of the teeth.

If a replacement timing chain does not match the original profile of the links, it will cause more noise. Also, the incorrect profile can affect the stability of the chain and cause the chain to whip. This is the root cause of premature wear and stretch. Some chain kits include new sprockets and camshaft phasers that are compatible with the new chain.

Water Pump

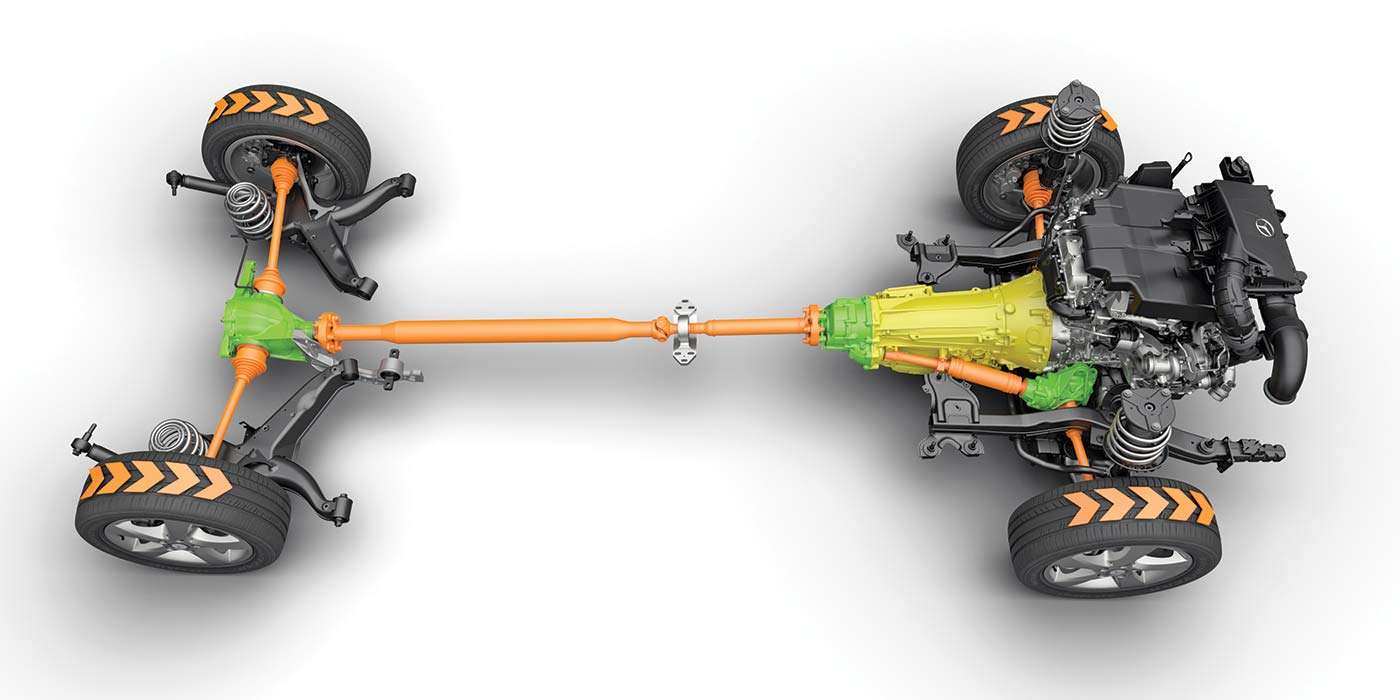

The traditional setup for a water pump is for it to be turned by the accessory belt drive system. It is simple and effective and allows for service if the water pump fails. But, its one disadvantage is the amount of force the belt puts on the pump’s bearing and seals.

One solution is to have the timing chain power the water pump. Since the chain has teeth that turn the pump, less force is put on the shaft, theoretically allowing it to last longer. But, since the pump is part of the engine’s valvetrain, servicing the pump is difficult.

In fact, at the top of the list of the most challenging water pumps to replace are those found in the Nissan VQ-Series V6 engines. The pump is turned by the timing chain and is nestled in the engine block. Whether the engine is mounted transversely or longitudinally, the job requires a significant amount of labor.

The first sign of water pump bearing failure will be a coolant leak coming from a hole on the block by the A/C bracket. This hole leads to the weep hole on the pump. The hole is between two seals that separate the oil on one side and the coolant on the other. If the outer O-ring fails, it will leak coolant into the front cover area connected to the oil sump. This could mimic a head gasket leak.

When replacing the pump, pay close attention to the O-rings. These need to be lubricated with either oil or coolant. The rings need to be able to seal and move small amounts as the block heats and cools. Do not use silicone or other sealants — doing so could block the weep hole in the block.