Models: 2005-’14 GM cars and trucks equipped with hydraulic steering

Customers may comment on a fluid leak under the front of the vehicle. Upon further investigation, the technician may find fluid leaking from the power steering system.

Diagnostic Information

Important: All potential leaks should be completely cleaned and identified before attempting to repair or replace any power steering components.

1. Start your diagnosis by inspecting the fluid level in the power steering reservoir. If the fluid level is not low, a careful analysis of the condition is necessary as it may involve a different type of fluid leak.

2. Visually inspect the components where the fluid has accumulated.

3. Before the component is replaced, inspect fittings and connections for proper torque. Clean the area around connections, joints and seals with engine degreaser.

4. Add fluorescent dye to the power steering fluid.

5. Start the vehicle and allow the power steering system to reach normal operating temperatures.

6. Turn the steering wheel to the stops in each direction while bumping the steering wheel against the stops 3-4 times. This will build maximum steering system pressure and help identify the source of the leak if present.

Caution: Do not hold the steering wheel against the stops as this will damage the power steering pump.

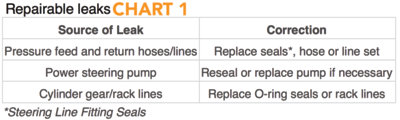

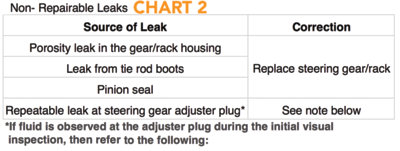

7. Determine the source of the leak. If a repeatable leak is found, refer to the following tables to determine the proper corrective action needed.

Some vehicles are equipped with a “duck-bill“ style seal that is pierced by the power steering line during installation to the gear at vehicle assembly. Vehicles equipped with this duck bill seal are:

• 2010-’14 Buick LaCrosse

• 2011-’14 Buick Regal

• 2007-’14 Cadillac Escalade

• 2013-’14 Cadillac XTS

• 2005-’14 Chevrolet Malibu

• 2007-’13 Chevrolet Avalanche, Silverado

• 2007-’14 Chevrolet Suburban, Tahoe

• 2007-’13 GMC Sierra

• 2007-’14 GMC Yukon, Yukon XL, Yukon Denali, Yukon Denali XL

• 2006-’10 Pontiac G6

• 2007-’09 Saturn AURA

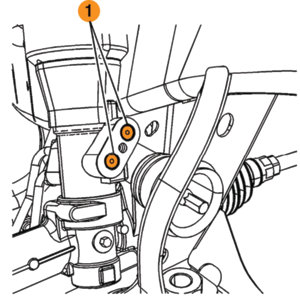

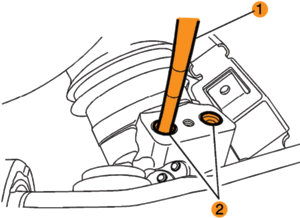

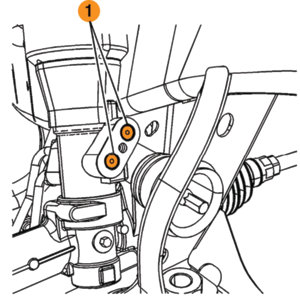

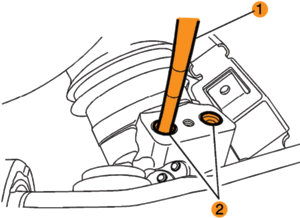

These seals are replaceable and any leak at the line to gear connection on these vehicles should be first addressed with a seal replacement. Use a J-42640 Steering Column Anti-rotation Pin (1) or equivalent to remove the seals (2) and then install the new seals by hand and connect the power steering inlet and outlet line. This will seat the seals into the steering gear housing.

Important: Only insert the anti-rotation pin just far enough in to the duck bill seal to get behind the duck bill seal’s steel ring. Then, using the tool, pry against steel ring to remove the seal. Do not insert the tool too far into the duck bill seal and pry against the housing bore. Prying against the housing bore could scratch the housing bore and require steering gear replacement.

•

Seepage at the adjuster plug may not necessarily indicate an active leak.

• You can distinguish seepage from an active leak by removing the left tie rod boot clamp and inspecting for the presence of fluid at the inner tie rod.

• If no fluid is found in the left tie rod boot, replace the boot clamp and clean the seepage (likely manufacturing residue) from the rack. No further action is needed.

• If fluid is found in the left tie rod boot, replace the gear assembly.

1. Start your diagnosis by inspecting the fluid level in the power steering reservoir. If the fluid level is not low, a careful analysis of the condition is necessary as it may involve a different type of fluid leak.

1. Start your diagnosis by inspecting the fluid level in the power steering reservoir. If the fluid level is not low, a careful analysis of the condition is necessary as it may involve a different type of fluid leak.

Seepage at the adjuster plug may not necessarily indicate an active leak.

Seepage at the adjuster plug may not necessarily indicate an active leak.