Models:

2001-‘14 Cadillac Escalade Models

2001-‘14 Chevrolet Tahoe and Suburban 1500

2001-‘13 Chevrolet Avalanche

2001-‘14 GMC Yukon Models

The electronic suspension control (ESC) system independently adjusts each of the four shock absorbers in order to provide an enhanced ride and improved control over a wide range of operating conditions. Based on input information from various sensors or from other systems through the serial data network, the ESC module can fine-tune the ride height and damping characteristics. The complexity of the system, however, makes it vulnerable to a few unique problems.

Owners of GM vehicles equipped with an ESC system may comment that they are experiencing one or more of the following suspension issues. Here are the four most common conditions we have identified and the recommended repairs:

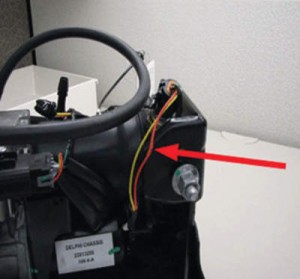

Condition 1: The “Service Suspension System” message is displayed on the driver information center (DIC) and the rear suspension ride height is incorrect. When checking for diagnostic trouble codes (DTCs), the ESC module will have DTC C0696 and/or C0711 set. This condition could be caused by the wiring to the automatic level control (ALC) pressure sensor being shorted to ground at the locations shown. See Figs 1 and 2.

Note: The air compressor assembly may need to be removed from the vehicle to determine if the wiring is possibly pinched between the compressor assembly and frame.

Condition 2: There is a “Service Suspension System” message on the DIC and the rear suspension ride height may be lower than normal under a heavy payload. When checking for DTCs, the ESC module will have DTC C0711 set. This condition may be caused by an internal fault in the ALC pressure sensor. This may occur due to moisture getting into the sensor.

Condition 3: There is a loose hose hanging down in the left rear of the vehicle. Upon inspection, it may be determined that the hose is damaged or has become disconnected from the air inlet filter of the ALC suspension air compressor.

Condition 4: The ALC compressor is no longer performing a self-test (compressor activating for a few seconds) at start up.

Recommended Repairs

Condition 1: Do not replace the complete air compressor assembly for this condition. Repair any damaged or shorted circuits and then reposition the wiring so it doesn’t get damaged again during the compressor assembly installation.

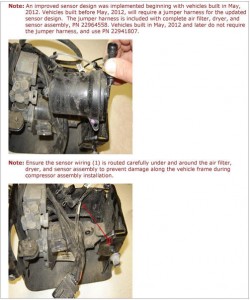

Condition 2: Do not replace the complete air compressor assembly for this condition.

Follow diagnostic procedures for DTC C0711 to determine if the ALC pressure sensor needs to be replaced. Note that the sensor is no longer serviced separately. When replacing the sensor, install a complete air filter, dryer and sensor assembly. Installing this complete assembly will provide a better repair than replacing the sensor only. See Fig. 3

Condition 3: Do not replace the complete air compressor assembly for this condition.

Replace the ALC compressor air inlet filter and hose assembly.

1. Safely raise and support the vehicle.

2. Release the air compressor air inlet filter (1 in Fig. 4) from the retainer (2 in Fig. 4). Secure the rear axle vent hose and compressor air inlet to the fuel fill pipe assembly.

3. Remove the remaining air inlet hose (3 in Fig. 4) from the air compressor.

4. Install the new air inlet filter and hose assembly. Ensure the air inlet hose (3 in Fig. 4) is routed as shown.

Condition 4: The automatic level system will not normally cycle the compressor when turning the ignition key on.

The ESC module checks the automatic level system pressure at start up. If the pressure is below 10 psi (69 kpa) then the module will operate the compressor to add air to the shocks as a replenishment cycle. This typically would only happen if the vehicle sat for a long period of time or there was a very small leak.

The correction for many of the ESC system conditions may be solved by one or more of the recommended repairs described above. Be sure to follow the diagnostic and repair process thoroughly and complete each step.

Written by the ALLDATA® Community Automotive Diagnostic Team, a select group of automotive experts dedicated to helping technicians fix hard-to-repair vehicles more efficiently. © 2014 ALLDATA LLC.