Tapered Wheel Bearings

Here’s what you should know as a technician when servicing tapered wheel bearings.

As technicians, you may have noticed that you haven’t seen tapered wheel bearings in many late-model vehicles. It seems that nearly every vehicle made these days will run some sort of wheel hub assembly. There are a number of reasons for this, but the biggest reason is this: ease of assembly. Not assembly for us, the technicians, but for the assembly line.

ADAS Module Programming

Reflashing and reprogramming is a necessary service for repairing vehicles.

Live Axle Wheel Bearing Service

Replacing rear wheel bearings on a live axle rear suspension requires a few extra steps when compared to a unitized bearing.

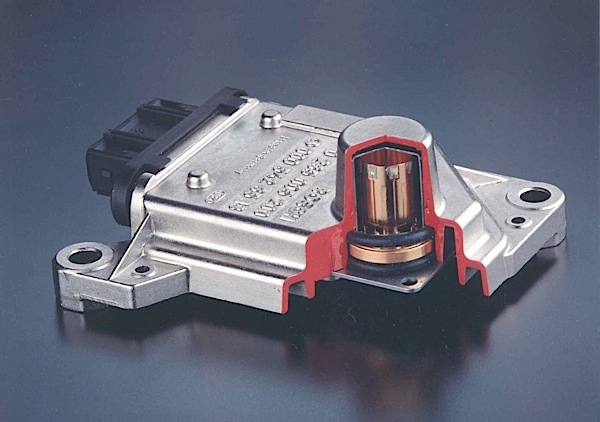

Ride Height Sensors

If one of these sensors is replaced, it must be calibrated after it is installed.

Ride Control For Electric Vehicles

Replacement units are available from sources other than the dealer.

Other Posts

ADAS False Activation Evolution

The logic behind most ADAS warnings or corrections is to examine the plausibility of the situation.

Understanding ADAS: Blindspot Detection Systems

With the right tools and service information, it is possible to resolve a customer’s complaint.

Understanding Passive Wheel Speed Sensor Operation

Passive types of wheel speed sensors are still used in many applications so understanding their operation is important.

Threadlocking Compounds For Vehicle Corners

To get the most out of these “liquid” tools, you first need to know how they work.