For a successful repair, the cylinder head gasket must seal fuel, air, vacuum, hot pressurized combustion gases, coolant, as well as high and low pressure oil. The following tips will help ensure that a quality repair is made.

1. Make sure the reason for head gasket failure is properly diagnosed – rarely does a head gasket fail on its own accord.

B. Make sure overheating engines are properly repaired.

C. Make sure all induction symptoms are working properly – detonation and pre-ignition will cause pre-mature gasket failure.

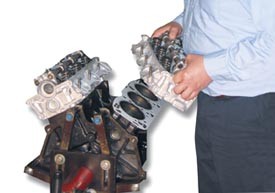

2. Make sure the head and block are in best condition possible – the smoother and flatter the better!

B. Make sure castings are thoroughly checked for cracks, pitting and scratches.

C. Make sure the head and block surfaces are as smooth as possible – make sure your machine shop knows what finish they are producing.

D. Never use abrasive disks on the head or block – these can lead to damaged or uneven mating surfaces that can cause internal or external leaks; always use a solvent and a soft scraper (rubber or plastic).

E. Handle newly machined parts with care – many times castings are scratched or damaged by careless handling after an expensive, high-quality finish is achieved.

F. Make sure mating surfaces are clean – all dirt and debris must be removed (use of RTV and other chemicals on head gaskets is not recommended for too many reasons to list).

3. Make sure proper bolt load is achieved – friction is the enemy.

B. Always clean old bolts with solvent and a soft bristled brush – do not tumble or wire wheel as damage to the threads can easily occur.

C. Bottom tap all holes in the block, making sure that threads are in the best possible condition.

D. Use light engine oil on bolt threads and under the bolt head – do not dip bolts in oil as hydraulic lock can occur in blind holes resulting in possible casting damage.

E. Always consult and follow the latest OEM torque specification – never guess as each engine is unique and many late-model applications torque specifications often change.

F. Periodically have your torque wrench calibrated – all precision shop gauges need to be periodically serviced to maintain their accuracy.

For additional information on cylinder head gaskets, visit Corteco’s website at www.corteco-na.com.

For additional information on cylinder head gaskets, visit Corteco’s website at www.corteco-na.com.