Eric Seifert

Automotive Technical Editor

As a sales manager, Paul relies on his car to get him to important sales meetings across the state. His 2005 Chevrolet Aveo has been his trusty ride for a couple of years now. Recently, he noticed a “crunch” noise from the front of the car while negotiating speed bumps. Paul was embarrassed that a client also commented on his noisy car. Finally, he called me for an appointment.

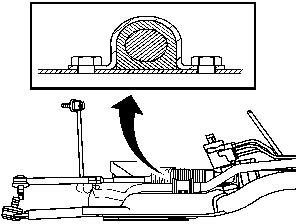

Some customers may comment on a crunch, squawk, or grind noise from the front suspension when driving over bumps at low speed. The noise may be more apparent in cold weather. This condition may be caused by friction between the stabilizer bar and the mount bushings.

Two GM P/N 96653351 (2004-2005 models) or 96653352 (2006 Model) Front Stabilizer Bar Bushings will be required to complete the repair.

Replace the bushings with the revised (new design) parts following the procedure below. Clean all residual grease from the stabilizer bar before installation.

Applicable Vehicles:

Applicable Vehicles:

• 2004-2006 Chevrolet Aveo; and

• 2004-2006 Pontiac Wave (Canada only) built prior to VIN breakpoint 6B518789.

Repair Procedure:

(Review safety procedures in the ALLDATA system before beginning.)

1. Raise the vehicle.

2. Remove the crossmember assembly.

3. Remove the old stabilizer bar bushings. Clean all residual grease from the stabilizer bar.

4. Install the new design stabilizer bar bushings.

5. Install the crossmember assembly.

6. Lower the vehicle.

Written by ALLDATA Technical Editor, Eric Seifert. Eric is an ASE certified Master Technician and Engine Machinist. He is a graduate of the De Anza College Automotive Technology Program, with 20 years of independent shop and parts store experience.

For information on products offered by ALLDATA, visit www.alldata.com.