Applied Vehicles:

• All 2000-’02 Frontier (D22) with a VG33E engine; and

• All 2000-’02 Xterra (WD22) with a VG33E engine.

An applied vehicle may exhibit:

• Engine coolant under the vehicle when parked; or

• Smell of coolant when the engine is warm.

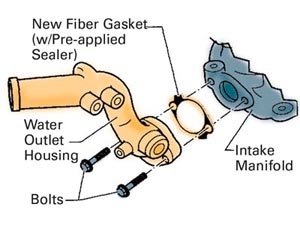

The cause may be coolant leaking between the water outlet housing and intake manifold sealing surfaces (See Figure). Refer to the Service Procedure to resolve this incident if it occurs.

Note: A leak from the above-noted area can be verified by a visual inspection.

Service Procedure:

Install the new fiber gasket between the water outlet housing and intake manifold as follows:

Caution: Be careful not to spill engine coolant on electrical connectors, drive belts, etc. when performing the following procedure.

1. Verify the coolant leak is coming from the water outlet housing/intake manifold sealing surfaces.

2. Use the valve on the lower radiator tank to drain coolant into a clean bucket (or other clean, suitable container), to just below the level of the water outlet housing.

Note: Draining the coolant below the level of the water outlet housing will minimize coolant spillage when removing the housing.

3. Remove the parts necessary to access the water outlet housing.

4. Remove the water outlet housing from the intake manifold.

5. Thoroughly clean the sealing surfaces of the water outlet housing and intake manifold, making sure all old sealer is completely removed.

5. Thoroughly clean the sealing surfaces of the water outlet housing and intake manifold, making sure all old sealer is completely removed.

6. Install the new fiber gasket onto the water outlet housing as follows:

a. First, install the two mounting bolts through the holes in the water outlet housing.

b. Then, slide the fiber gasket over the bolts until it is flush against the sealing surface of the housing. The bolts will keep the gasket in place while installing the housing.

7. Install the water outlet housing to the intake manifold and tighten the bolts to 16.3-20.3 Nm (12-15 ft.-lbs.).

8. Reinstall all components that were previously removed.

9. Refill the radiator with the coolant that was drained and captured in step 2, and according to the Coolant Refilling Procedure outlined in the “MA” section of the applicable service manual, to ensure air bubbles are purged from the cooling system.

Note: If additional coolant is needed, use a 50/50 mixture of Genuine Nissan Antifreeze Coolant (or equivalent) and distilled water or demineralized water.

10. Run the engine and confirm there is no coolant leak(s).

Technical service bulletin courtesy of ALLDATA.

For additional tech tips, visit www.alldata.com.