There is a cylinder head gasket design change for 2002 Chrysler PT Cruiser 2.4L VIN B engines. The hole size opening was changed to improve the ability of oil drainback from the cylinder head and also improve crankcase ventilation on 2002 Chrysler PT Cruiser 2.4L VIN B engines. Beginning in 2002 this opening was reshaped to a much larger size.

There is a cylinder head gasket design change for 2002 Chrysler PT Cruiser 2.4L VIN B engines. The hole size opening was changed to improve the ability of oil drainback from the cylinder head and also improve crankcase ventilation on 2002 Chrysler PT Cruiser 2.4L VIN B engines. Beginning in 2002 this opening was reshaped to a much larger size.

A new cylinder head gasket was designed to fit the new cylinder head with C/N 04667086. The 2002 block was also modified to reflect the cylinder head revision. With the implementation of the improved engine oil return and crankcase ventilation (enlarged hole), it became necessary for the 2002 and newer head gasket revision.

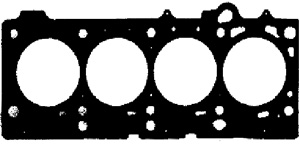

The design change to the cylinder head gasket was made to cover the new larger crankcase ventilation enlarged hole. The hole, marked in Figure 6, is between cylinders No. 3 and No. 4 on the 2002 head gasket. Only one of the oil drainback holes on the flywheel side is opened from a round hole to a slightly larger irregular shape.

The original hole was much smaller and is the reason the gasket will not fit properly on the earlier 2001 and older cylinder heads and blocks.

Although the earlier 2001 gasket can physically be installed on the 2002 head and block, it will leak oil from the uncovered oil return/ventilation hole in the cylinder head when the engine is run. It will also block openings. The oil hole between the cylinders is not a high-pressure oil passage.

The revised 2002 head/block may be installed on 2001 vehicles, so exercise caution when assembling these engines, as well as when buying cores.