By Jeff Webster, ALLDATA

You or a customer who drives a Chrysler minivan may notice oil wicking from the oil filter gasket or the oil cooler gasket. Inspect the oil filter or oil cooler gasket for scratches or cuts. If any damage exists, perform the Repair Procedure.

Vehicles affected: 2001-’03 Chrysler Town & Country, Dodge Caravan, Plymouth Voyager with a 3.3L or 3.8L engine.

Repair Procedure 1. Raise the vehicle on a hoist.

1. Raise the vehicle on a hoist.

2. Remove the oil filter.

Caution: When servicing the oil filter, avoid deforming the filter can by installing the remove/install tool band strap against the can-to-base lock seam. The lock seam joining the can to the base is reinforced by the base plate.

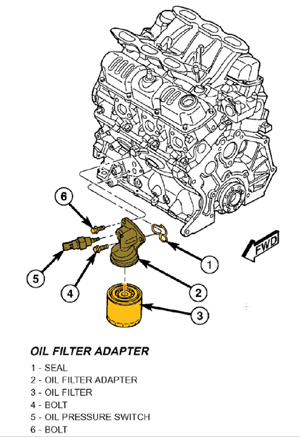

a. Using a suitable oil filter wrench, turn the filter counterclockwise to remove from the oil filter adapter (see Figure 1). Properly discard the used oil filter.

3. Remove the oil cooler attachment fitting and oil cooler, if equipped.

4. Disconnect the oil pressure switch electrical connector.

5. Remove the oil filter adapter attaching bolts.

6. Remove the oil filter adapter and seal.

7. Install the revised oil filter adapter, P/N 04781163AC, and gasket, P/N 04781166M. Tighten the attaching bolts to 28 Nm (250 in.-lbs.).

8. Connect the oil pressure switch electrical connector.

9. Install the oil cooler with the new gasket, P/N 05093807M. Tighten the oil cooler fitting to 27 Nm (240 in.-lbs.).

10. Lower the vehicle on the hoist.

11. Fill the oil to the proper level.

12. Start the engine and inspect for leaks.

Courtesy of ALLDATA.

For additional information, visit www.alldata.com.