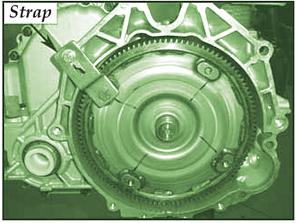

New and remanufactured transaxles are shipped with a retaining strap to hold the torque converter in place. See Fig. 1.

Note: Do not remove the strap until the transaxle is mounted on the transaxle jack and ready for installation. If the strap is removed prior to this step, the torque converter may move out of position in the housing.

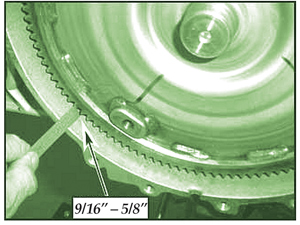

If the torque converter has moved from the fully inserted position, carefully push the torque converter inward and rotate it until the converter is recessed approximately 9/16-5/8” (14-16 mm) into the transaxle case. See Fig. 2.

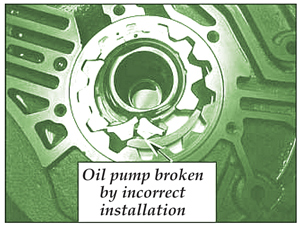

If this procedure is not followed, the oil pump may be damaged during installation of the transaxle. See Fig. 3.

Courtesy of IDENTIFIX.

For more information, visit www.identifix.com.