How stability and traction control systems will change the industry as we know it. I hear all of the moaning and groaning out there about how new cars are better made, require less maintenance and break down less often. But, they still need to stop and this means they will always need brakes. Brake pads and rotors are here to stay, and the market is predicted to get even better in the future. It is my prediction that what the “check engine light” did for the underhood repair market, the traction/stability control light will do for the brake repair market.

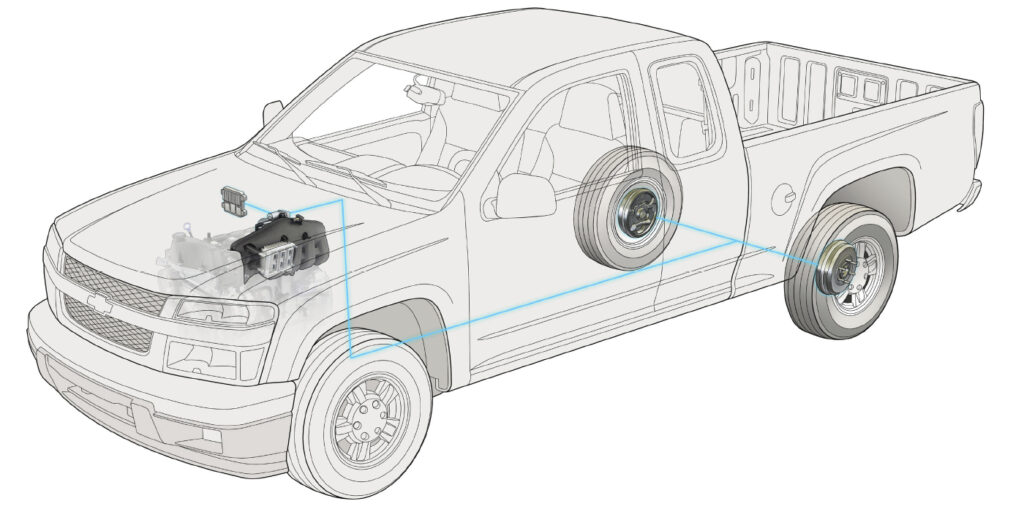

In their commercials, many automakers make keeping the vehicle on the road using new traction and stability control systems seem like magic. Ask any driver how the systems work and he will just shrug. Technicians know that it is the brake system that is responsible for this new level of safety.

Brake pads on a rotor now increase traction, keep the car on four wheels and even help a car turn a corner. Also, they can help some AWD vehicles mimic or simulate locking differentials while off roading. It all comes down to brake pads pinching a rotor.

It is my prediction that in the next decade, processing speeds of the body-control computers will drastically increase. Also, wheel speed sensors will not only measure wheel speed, they will measure torque generated by the brakes and engine in real time. The computer will be able to look at the friction levels of the brake pads and determine if the pad is below standards and turn on a “check brakes” light. Also, these systems will even be able to tell if there is a pulsation problem long before the driver can feel it. Gone will be the days of $99 pad swaps and substandard $9.99 do-it-yourself brakes pads.

The industry must make consumers aware that it is the brake system that is doing the all work for traction and stability control. Most consumers think that it is the hand of God that is saving them. This is a public service message that the aftermarket and automakers must undertake in the near future. If consumers understand that the brake pads and rotors ultimately decide their fate, they will become more aware of the importance of brake service.

Today’s automotive safety campaigns always seem to show the vehicle almost hitting a child, pet or unmovable object. For this campaign, we need blood and guts, just like in the old days. Show an SUV on its roof or a car taking out a guardrail — it is the only way you are going to get the public’s attention. Let’s not have a repeat of the 1990’s ABS public information campaign that left the public with more questions than answers.

The other side of this double-edged sword is the new level of knowledge needed to service these systems when the traction and stability control light comes on. It will take scan and scope tools to solve these problems, along with large dose of theoretical electrical knowledge. This means investing in tools and training.

The future is bright if you are prepared to deal with it.