Winter and fall are the seasons when brake lines and hoses fail. It typically happens when roads are slick and the ABS system or customer hammer the brakes with higher than normal pressures.

Inspecting brake lines should be part of every vehicle inspection. Spotting and replacing a corroded line before it bursts can save the driver not only from an accident but possibly damaging the master cylinder and ABS modulator.

OE brake lines are made from sheet metal that is rolled and welded into tubing. To seal the tubing, molten copper alloy is poured into the line. On the outside, a galvanized or plastic coating or plating material is applied. In rare cases, lines are made from stainless steel. While stainless steel is corrosion resistant, it is very hard and brittle, requires special tools to bend and is difficult to flare.

Moisture and the depletion of the corrosion inhibitors in the fluid are the main sources of fluid breakdown internally. Corrosion causes the copper to be leeched from the tubing and deposited in the brake fluid. While it is rare for a brake line to fail completely from this type of corrosion, it can lower the integrity of the metal shell over time.

The main killer of brake lines is abrasion. When the external coating is removed by road debris or rubbing on other components, the line will soon develop corrosion. The corrosion will spread and get under the coating. Soon, the integrity of the line will be compromised. This corrosion is hastened by road salt and deicers that become alkaline from reacting with the tubing.

Some automakers have changed the way they route and protect brake lines. It is not uncommon to see plastic covers over brake lines. Also, some manufacturers will minimize exposure of the lines by routing them in the wheel wells.

Materials are not changing. Steel is still the material of choice for OEMs. What has improved are the coatings used on brake lines, which are tougher against abrasion.

Fabrication vs. Pre-bent

Fabricating new lines has gotten easier as new tubing materials and tools have been introduced to combat corrosion repairs.

Flexible brake tubing made of copper and nickel that can be bent on the vehicle has been growing in popularity. This material is corrosion-resistant and softer than mild steel. This softness makes flaring the connections easier and less prone to leaks. Traditional brazed mild steel tubing is getting better as well, with better coating and plating protection that can resist corrosion.

New tools on the market can flare a line while you have one hand tied behind your back. More expensive bending tools allow you to make bends tighter and closer to the fittings without deforming the line.

Pre-fabricated lines are also becoming more readily available and offer better coverage. These lines can be ordered as individual lines, or as complete sets for the vehicle. These match the line runs and flares for the vehicle.

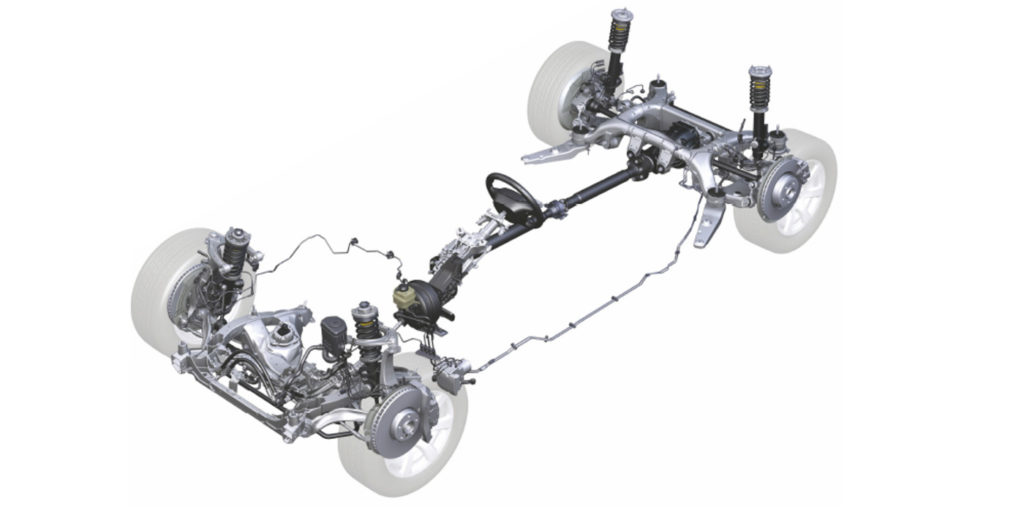

Pre-bent lines for some vehicles are available from aftermarket sources and new car dealer parts departments. These match the original lines exactly. But, it might require a lot of disassembly because brake lines are installed before the frame or suspension subframes are installed.

Before you replace a brake line, look at the vehicle to decide which repair method is the more economical for the customer. But, make sure you also look at the productivity of the technician and shop. While fabricating a line in-house might be the least expensive option for the customer, a pre-fabricated line will often reduce the amount of labor, permitting the technician to move on to other jobs and vehicles.

Inspection Tips

Always pay attention to the position of the line that is exposed to road splash. This is the area of the line that will fail first due to abrasion.

Flaking or lifting of the outside coating is the first clue corrosion has set in. This is a clear sign the external coating has been breached and corrosion is starting on the lines.

Look at the lines that pass above the fuel tank. This area can become very corroded from the buildup of deicing brines and road salt that can’t be washed away. A rainstorm in July, for instance, could activate the compounds and cause winter corrosion in the middle of summer. A boroscope can help to inspect the lines in this area.

Document the condition of the lines. Taking pictures and making notes on the repair order can save you a trip to court. A few years ago, a manslaughter case was made against a mechanic because he did not tell the customer about corroded lines during a state inspection. Three months after the inspection, a leaking line caused a serious accident.

Inspect brackets and hold-downs. When a brake line is free to move, it can rub up against another line. As the vehicle shakes and vibrates, outer coating can be rubbed away.