How Regenerative Brakes Operate

Regenerative braking is a hybrid’s first choice for braking.

A hybrid vehicle is a different animal than many of us are used to seeing. After all, if the engine of a typical vehicle stalled out at a traffic light, the driver of that vehicle would know something was wrong with it. If that same vehicle still drove with the engine off, then that would mean they were probably going down hill. But, in the hybrid world, that is all normal. Systems around the vehicle are impacted by two key features:

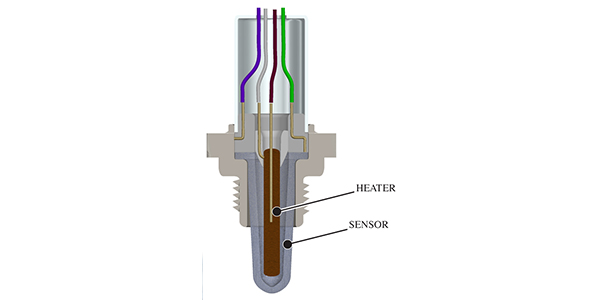

Oxygen Sensor Heater Codes

An oxygen sensor code related to the heater circuit can be difficult to cure.

Catalytic Converter Replacement

Converters must be certified and labeled with the correct codes that are stamped into the shell.

Determining Catalytic Converter Efficiency

Tiny details can limit the life of a catalytic converter.

Stainless Steel Did Not Kill The Exhaust Repair

Direct fit parts can be used to make an effective repair quickly.

Other Posts

Benefits of Using Brake Parts Designed to Work Together

When replacing brake system components, it might seem like using compatible parts from any manufacturer – regardless of brand – should get the job done. However, for the safest brake job with the best performance, it’s always best to use parts from the same manufacturer, like ADVICS, where our brake pads, brake rotors, hydraulics, calipers

Tesla Wheel Bearing Replacement

The process of replacing the hub unit on a Tesla is the same as many cars and light trucks.

Brake Pad Edge Codes – What Can They Tell You?

The edge code is a language written by engineers, federal entities and industry associations.

Brake Problems

Reducing brake drag on late-model vehicles is not accomplished by a single component; it takes a system.