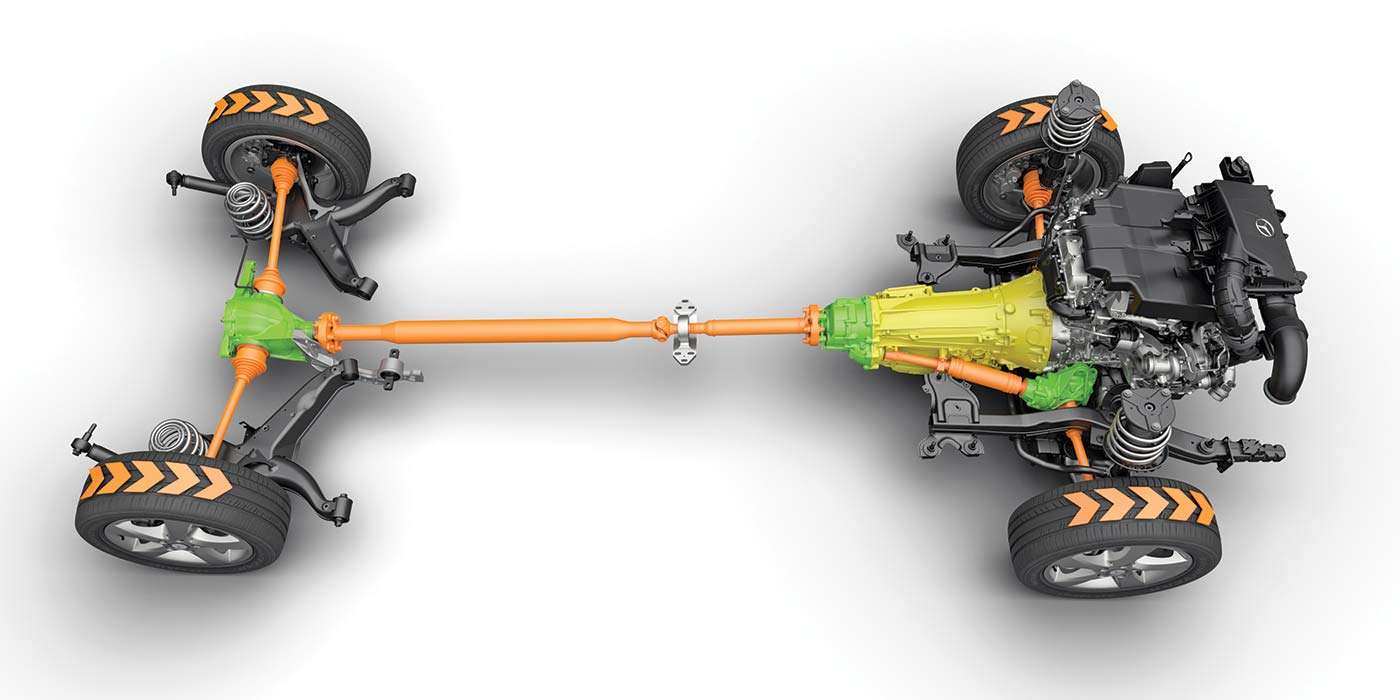

AWD is always engaged and with the ABS brake modulator, can perform like systems with limited-slip differentials.

Many AWD systems came onto the market in the 1990s. Unlike 4x4 truck systems of the day, these systems were always engaged. Many of the early systems used electro-mechanical ways to manage the distribution of power to thefour wheels.

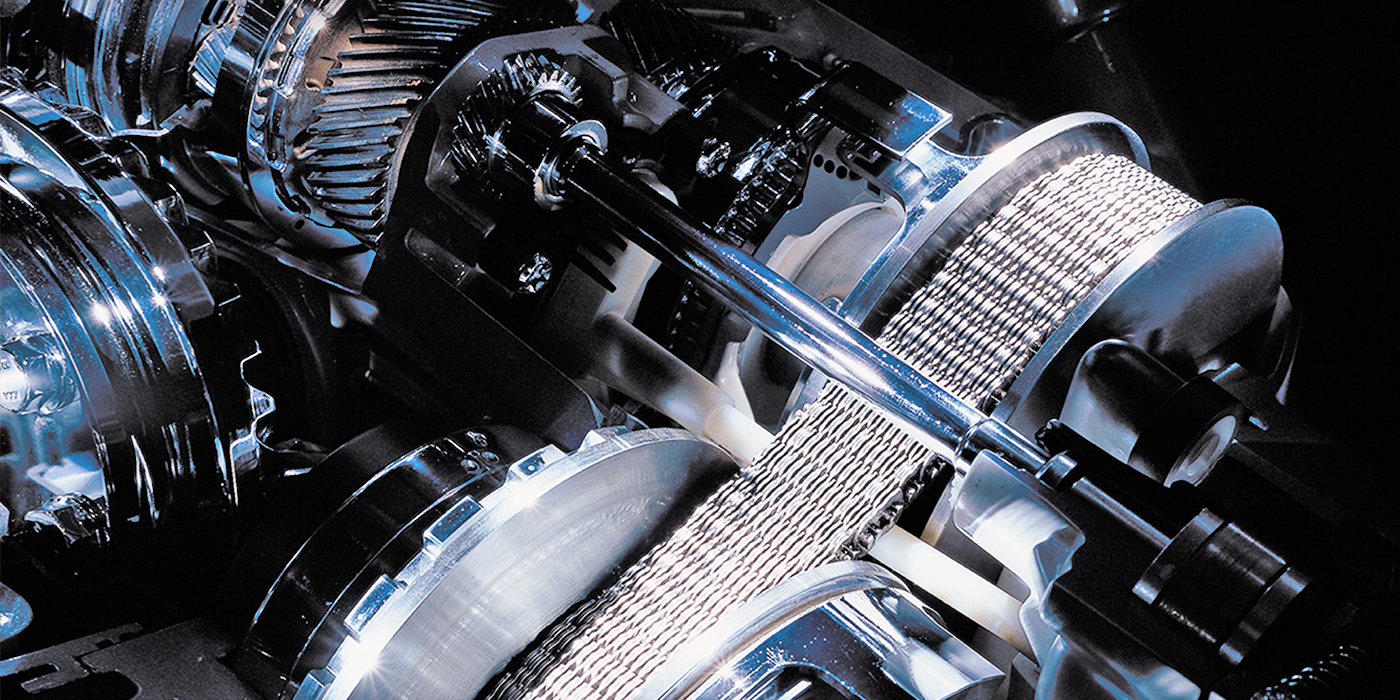

Most of these systems used viscous differentials and limited-slip differentials with special fluids inside. These components were prone to failure and are expensive to manufacture. The performance of these systems could also be challenging to control with sensors and actuators.

This tech tip involves complaints about brake noise in a Ford Escape Hybrid’s system.

Knowing what the common issues are & understanding the options available to isolate & fix problems are the keys to success.

No matter the manufacturer, there is almost always an all-wheel drive (AWD) option.

Parts that wear out must be replaced.

The transfer case is a rather unique design in the way that it operates a clutch pack mechanically, not hydraulically.

You need to know how transmission fluid flows inside an automatic transmission.

Can a bump set a wheel speed sensor code?

There are three types of modern driveshafts with multiple configurations.