Following a new clutch installation, there is nothing worse than experiencing slipping or release problems. Many times installers even begin to believe that the new clutch kit is defective. This is not correct, in most cases! The majority of the time, a simple, quick adjustment will alleviate any problems. Most Japanese/Korean imports utilize an adjustable clutch master cylinder. When a new clutch kit is installed, the master cylinder needs to be re-adjusted to work properly with this new kit and avoid release and slipping problems.

Following the steps listed below demonstrate the proper way to adjust the master cylinder and avoid potential release problems with the new clutch:

Preventing No Release:

1. Verify that hydraulic fluid is clean and that correct fluid was used.

2. Locate the master cylinder push rod that attaches to the clutch pedal.

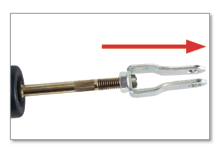

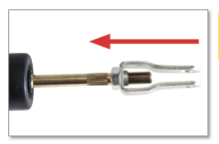

3. Using the picture (Fig. 2) as reference, extend the push rod to allow for more throw. After the rod has been extended, tighten the locking nut.

Caution: DO NOT extend the rod out too far. Extending too far out can block the compensating port in the master cylinder.

Preventing Slipping:

1. Verify that hydraulic fluid is clean and that correct fluid was used.

2. Locate the master cylinder push rod that attaches to the clutch pedal.

3. Using the picture (Fig. 3) as reference, shorten the push rod

to allow for less throw. After the rod has been shortened, tighten the locking nut.

Note: In a slipping situation the rod is too long, causing the compensating port to be blocked off not allowing fluid to return to the fluid reservoir.

Courtesy of Schaeffler Automotive Aftermarket, manufacturer of LuK Clutches.