No. 1: Don’t neglect the importance of the pre-alignment inspection.

The more thorough the pre-alignment inspection, the better your chances are of not overlooking something that might cause a comeback after the wheels have been aligned. The most neglected inspection item is tire inflation. Even the most precisely aligned toe angle will still pull if the pressures are not even.

Some drive-on lifts include an inflation station at each wheel so the pressures can be adjusted automatically.

No. 2: Don’t forget to reset the steering position sensor!

In order of some stability control systems to function, the steering position sensor must be recalibrated after the toe or thrust angle is changed. Some vehicles require that the recalibration be performed through the OBDII port.

A scan tool can be used or Hunter’s CodeLink tool which is programmed to perform vehicle specific calibrations. Hunter has simplified the process with a seamless transition from the final front toe adjustment to the required reset.

No. 3: Do a complete alignment.

Time is money, so the faster you get the job done the more money you make, right? Wrong. If you don’t do a good job because you’ve skipped things like checking toe-out on turns, ride height, SAI, caster (if nonadjustable), rear-wheel alignment (if nonadjustable), the condition of steering and suspension parts, etc., you may end up having to do the job over again.

No. 4: Don’t try to align worn parts.

To hold an accurate alignment, steering and suspension parts must be in good condition, which means no more play than allowed by the vehicle manufacturer. Always refer to a reference manual for the exact specs since acceptable ball-joint play can vary considerably from one application to another.

As parts wear, they get progressively looser and are less able to maintain accurate wheel alignment. If a tie-rod end or ball joint is borderline, it’s better to replace it now.

The most missed item is bushings. With so many vehicles using alumium cotrol arms or links with large bushings, bad bushings can be hard to spot. Often the manufacturer will publish specifications and testing methods in the repair manual.

No. 5: Don’t just set the toe and let it go.

If a front-wheel-drive car has no factory adjustments for camber or caster (Honda, for example), don’t just set the toe and let it go — always read all the angles. Why? Because if there’s a problem, a simple toe adjustment won’t fix it.

Many so-called “nonadjustable” suspensions can often be easily adjusted with the help of various kinds of aftermarket alignment aids. If you’re not already familiar with the use of camber/caster shims, caster wedges, offset bushings and the like, get some catalogs from the specialty alignment-product suppliers and find out what’s available.

No. 6: Set to the factory-preferred specs, not rule-of-thumb specs.

There are no such things as “rule-of-thumb” specs when it comes to wheel alignment. What works on one vehicle may or may not work on another. Front-wheel-drive cars usually require different toe settings than rear-wheel-drive cars. Vehicle weight, chassis design, chassis loading, tire size, driveline configuration and intended use all affect wheel-alignment settings that the vehicle manufacturer develops for the vehicle.

Also, pay attention to the tolerances on cross caster, camber and toes specifications. The mark of truly great alignment technician is to be able to look at the specifications and determine if there will be a problem.

No. 7: Compensate for how the vehicle is driven and used.

Vehicle loading can have a very pronounced effect on wheel alignment. If a vehicle that’s normally loaded with passengers or cargo is aligned while empty, the tires will likely exhibit rapid wear because they won’t be running true when the vehicle is driven while carrying its normal operating load.

No. 8: Align all four wheels, not just the ones up front.

Four-wheel alignment has become much more commonplace in recent years, but there are still those who won’t align all four wheels because the customer doesn’t want to pay “extra” for a four-wheel alignment.

This may be more of a marketing problem than a technical one, but the public needs to be educated that the rear wheels have just as much influence on where a vehicle goes as the ones up front.

No. 9: Speed is King: Pre-Alignment Checks

It is a fact, the shop who first measures the alignment angles of a vehicle will typically align it. Being able to sell an alignment to a customer can be easier if a real need can is present with measured angles rather than selling the concept and benefit of an alignment.

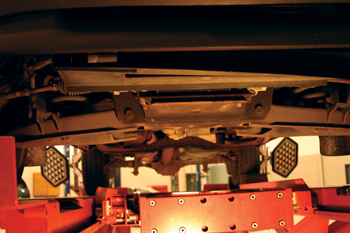

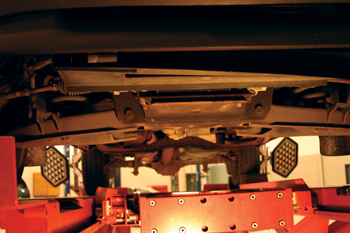

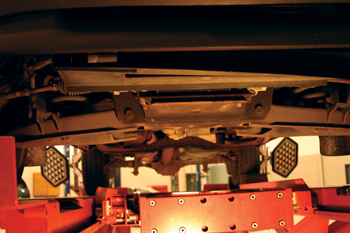

Alignment equipment manufacturers are creating alignment equipment like better wheel clamps, sensors and lifts to measure angles faster.

If angles can be measured quickly, it is possible to sell more alignment while also being more productive and profitable.

No. 10: Test drive the vehicle before it’s returned to the customer.

A simple test drive can reveal a lot of problems that might have been otherwise overlooked. Sure, test drives take time, but so do comebacks. Think of it as a final quality-control check.