Just like any other typical day, a car will be brought to your shop by a husband, wife or friend who will tell you there is a noise they haven’t actually experienced, but the primary driver wants it “looked at”— translation: “fixed.”

We always want to speak to the person who has experienced the problem to get the first-hand story of the who, what, why, where and when. This gives us all the necessary information for the technician to have an accurate complaint from which to work.

As was the case with this particular car, a 2009 BMW 3 Series coupe (E93 chassis), there was a knocking noise in the front of the car during slow parking lot driving when the brakes were quickly applied. You know, like when you finally see that up-close parking space you’ve been driving around trying to find.

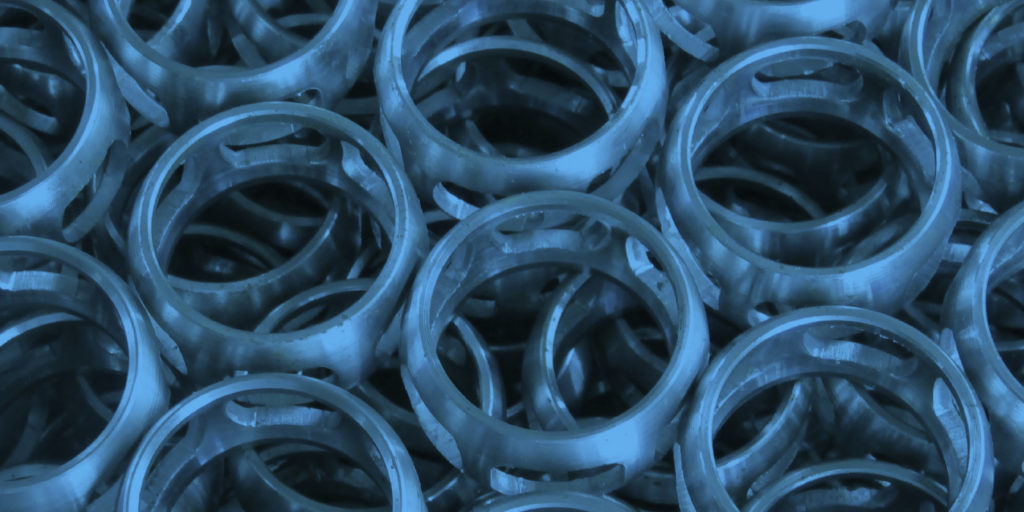

Once we were able to determine where the noise was coming from and how to duplicate it, it was time for the inspection. When the vehicle was on a service lift, we saw right away that the front suspension arm bushings were leaking their hydraulic fluid. See Photo 1 where the fluid is leaking out

Step one is deciding what to call the part. Some parts departments still call them control arms, while others refer to them as torque rods or thrust rods. The online BMW parts catalog we use calls these arms “tension struts” on one page and “radius rods” on another!

With so many names for the same part, you’ll want to make sure you identify the suspension parts correctly, based on who you call to order them.

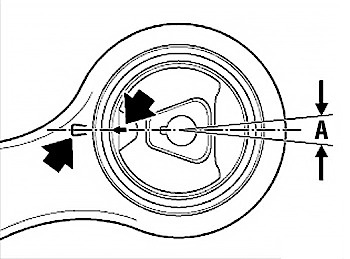

These bushings need to be pressed in, so proper care is important here (See photos 2 and then 3; image courtesy of ALLDATA). Follow the work instructions, use the correct adapters, keep the area clean, and remember that the bushing placements are important! Do not deviate more than 5 degrees.

Also, be sure to perform a complete wheel alignment. That means checking and adjusting the front and rear. We see many cars come in, and the owners are being told they don’t need to perform a new alignment on the car if there is no visible tire wear (if you’re waiting to see tire wear, it’s too late to extend the tire life!). Every year, the alignment should be checked to be sure your customers are getting the best possible tire life, handling and fuel mileage.

TECHNOLOGICAL ADVANCEMENTS

When you think about the way technology has advanced on cars and trucks, do you think electronic controls, computers and networks? I know I always did. Then I started to look closer at some of the items we take for granted, such as suspension bushings.

It didn’t seem that long ago when all suspension bushings were a combination of steel or aluminum and good, old-fashioned rubber. The rubber prevented the various metal parts from direct contact. Over time, the rubber parts would wear out and crack, and we would replace them as needed.

It’s not uncommon for an older BMW with a bad rubber control arm bushing to experience a few inches of front wheel movement just as the vehicle comes to a stop with a pretty firm clunk.

The latest advancement in bushing design is hydraulic or oil-filled control arm bushings. Why such a change in a simple component, you ask? It’s in response to the consumers’ desire for smoother, quieter and better-handling cars. That means more sophisticated suspension components. (Full disclosure: the parts perform the same function, but have new names, like wishbone, tension strut and torque strut.) The control arm bushing is actually called a hydro bearing in the BMW catalog (because of its hydraulic damping mechanism).

It turns out these bushings are “tuned” to the suspension of the vehicle. They are designed with a certain tire and wheel combination, and are manufactured to isolate wheel body frequencies and vibrations from the vehicle.

This may explain why we see cars with custom (large) wheels and tires in need of suspension work more often.

REPLACEMENT TIPS

Here are a few tips when dealing with original equipment hydraulic bushings.

- Look for leaking fluid. These bushings will leak fluid and should be replaced when they do.

- There are no sensors yet, so a visual inspection during each service visit should be performed. Remember, any worn suspension component can affect braking and handling. And, tire wear may increase due to worn suspension components.

- Always make sure you’re using the right tools and procedures when replacing the bushings; using the wrong tools can damage the control arm. Some bushing too

Photo 4 ls are designed for steel control arms only. Some press work is needed here — a damaged arm must be replaced, and by damaged, I mean one with nicks and bumps.

- Never use aftermarket “upgraded” rubber-only components. These are often marketed as an upgrade replacement. But, keep in mind that it’s not an upgrade when the car is designed for a hydraulic replacement. See photo 4.

- Since the wheels are already off, it’s a good opportunity to balance them, and remember to always perform a complete alignment — front and rear.

Following these tips and best-practice procedures will ensure not only a quality job, but also a very satisfied customer.