By Gary Goms

Import Specialist Contributor

Several years ago, the phone rang about 10 a.m. with a voice on the other end introducing herself as the service writer for a well-known import shop in a nearby state. The conversation revealed that the son of a very good customer had broken the timing belt on his 2000 Toyota 4Runner. Based upon the mileage of the vehicle, the import shop had previously recommended a timing belt replacement on the 3.4 L engine, but the owner had postponed the replacement until after his planned trip.

According to the service writer, the 4Runner had spent several weeks at a shop in a neighboring community having a new timing belt and water pump installed. The neighboring shop evidently couldn’t get the engine to start, so the service writer asked if I would have time to check it out and, if possible, get their customer’s vehicle on the road again. Obviously, there was more to the story than just a broken timing belt, but I, nevertheless, agreed to take on the mysterious cranking, no-start diagnostic project.

THE REST OF THE STORY

|

| The initial inspection indicated that the camshafts were timed correctly. |

Later in the day, the young owner called and I learned that he had driven the Toyota off the road during a bad wintertime white-out condition. A towing company had winched the Toyota back onto the road and the owner had proceeded up a steep mountain pass only to have the engine suddenly quit.

Several questions arose from the two conversations. My original impression was that the timing belt had broken immediately after the vehicle had been pulled back on the road. During wintertime white-outs, the timing cover often fills with snow, which freezes on the belt and causes the belt to jump timing or to break.

In this case, however, the belt had broken after the vehicle had been underway. As to why the original shop couldn’t get the engine running, I was completely mystified, other than to attribute the problem to a failure in the engine electronics. With an electronics failure in mind, I agreed to accept the vehicle for diagnosis on a time-as-available basis.

After the towing company dropped the vehicle off at my shop several days later, it was apparent that the vehicle had suffered major collision damage from colliding with a frozen snow bank. I moved the Pathfinder into the shop, recharged the battery and cranked the engine. The engine spun freely, which indicated that it was lacking compression. On the 3.4L Toyota engine, the upper timing covers can be removed to visually check camshaft timing. In this case, both camshafts seemed to be in time.

INTERFERENCE & NON-INTERFERENCE

|

| The abnormal 80% cylinder leakage on some cylinders was a combination of valve, head gasket and piston ring leakage. |

The next step was to perform a compression test. Because the compression on the driver’s-side cylinder bank ranged from about 60 to about 80 psi, my initial determination was that the valves were bent. Although my shop manual indicated that the 3.4L engine was, indeed, a valve interference engine, I was told by the customer’s home shop that, according to their information, the 3.4 was a non-interference engine and that this shop had never seen a 3.4 engine bend valves during a timing belt failure.

Suspecting that a sheared harmonic balancer key was causing the camshafts to run out of time, I disassembled the front of the engine. My first discovery was that, even though the water pump had been replaced, there was no coolant in the radiator. After removing the radiator, I discovered that the bottom header tank had been broken during the collision. Proceeding further, I verified that the woodruff key and locating pins on the harmonic balancer and timing belt sprockets hadn’t sheared.

The fact that the engine had arrived fully assembled with a broken radiator and no coolant in the engine block threw my initial diagnostic strategy completely off track. Because the radiator was broken, I began to theorize that the engine had lost coolant immediately after the accident. I also began to theorize that the original timing belt broke, not because of age, but because severe overheating and cylinder head warping had caused one or both overhead camshafts to seize in the cylinder heads.

Running that scenario through my mind, it was apparent that, without sufficient coolant, the engine temperature gauge wouldn’t register an overheating condition during a sprint up a steep mountain pass. The young owner, therefore, had no warning of the loss of coolant or of the impending engine failure.

A FORENSIC DIAGNOSIS

At this point, the diagnostic scenario had gone from a simple electronic failure to a major engine failure. I don’t do major engine repairs or replacements, so I called a Toyota dealership and an independent engine rebuild shop for a ball-park figure on replacing the radiator and repairing or replacing the engine. The estimates ranged from between $6,000 to $8,000, depending upon whether the cylinder block and heads were salvageable or whether the engine would have to be replaced with a new or remanufactured unit. When the cost of engine replacement and collision damage was added together, the vehicle looked like a total loss.

|

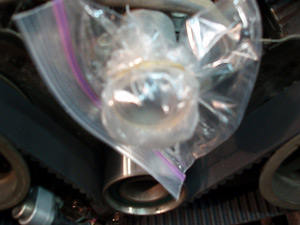

| When the plastic bag inflated, it was clear that the cylinder head gaskets were leaking. |

Because I concluded that the accident had caused the engine failure, I advised the young man’s father that he should contact his insurance company before he spent any money on repairs. Realizing that the owner’s insurance company would demand evidence that the engine failure had been caused by the accident, I began a forensic diagnosis to prove that the broken radiator had ruined the engine.

I performed a cylinder leakage test to see if the compression loss was through the valves or the cylinder heads. If the heads were cracked or the head gaskets were blown, the engine short block assembly might also have suffered from overheating damage. For insurance purposes, if the leakage was only through the valves, the engine might be successfully repaired by reconditioning the cylinder heads. If the heads were warped beyond repair and the condition of the engine’s short block assembly was questionable, the engine would need to be replaced. The question was how to separate valve, cylinder head gasket and piston ring leakage.

A DIAGNOSTIC STRATEGY

In general, measuring cylinder leakage requires that the piston be at top dead center on the compression stroke with the valves closed. Unfortunately, the cylinders were leaking so badly that I had no way of knowing exactly when the valves were closed. With that in mind, I chose to remove the timing belt so I could rotate the camshafts independently of the crankshaft. Although this strategy would be risky on valve-interference engines, this engine was already damaged and there was little to lose in justifying the insurance claim.

In this case, I attached the cylinder leakage tester to a cylinder and then rotated the camshaft until the cylinder leakage reached its lowest level. At that point, I then determined if the valves, head gaskets or piston rings were leaking compressed air from that particular cylinder. The cylinders ranged between 60 and 80% leakage, which is far beyond the 10-20% specification for normal engines.

Looking at the engine, I decided to cap off the thermostat housing outlet and water pump inlet with a plastic bag held on by a rubber band. If compressed air was leaking into the water jacket, the plastic bags would inflate. If compressed air was leaking through the valves, I would hear it through the throttle body and exhaust pipe. If a camshaft were broken, a few cylinders would show maximum leakage, while others would show minimum leakage.

Last, if the piston rings were stuck and leaking, compressed air would be rushing out of the engine’s crankcase ventilation valve and ventilation inlet hose.

Amazingly, the plastic bags inflated. Most of the cylinders also had air seeping from both the intake and exhaust ports. The percentage of leak varied among the cylinders. Most of the valves were obviously leaking, and the head gaskets were leaking on the center cylinders. Although none of the sources I contacted had ever witnessed bent valves caused by a timing belt failure, I would speculate that, on a severely overheated engine, the valves would indeed contact the pistons and bend when the belt broke. As for the piston rings, air leakage was apparent at the PCV valve and inlet, so one could only speculate how badly the pistons and piston rings were damaged.

THE CASE SUMMARY

In this case study, the diagnosis was complicated by having to estimate the damage for an insurance company. Remember that, including the collision damage, radiator replacement and engine replacement, the vehicle was close to becoming a total loss.

After forwarding photos of the broken radiator, frontal damage and diagnostic findings to the insurance company, the claims adjustor made an allowance on a replacement engine based upon the mileage of the vehicle and a full coverage of the collision damage. In this instance, I billed not only for the diagnosis, but also for the time spent assembling estimates and dealing with engine shops and the insurance company. With that done, I closed this case and went on with “business as usual.”

Gary Goms is a former educator and shop owner who remains active in the aftermarket service industry. Gary is an ASE-certified Master Automobile Technician (CMAT) and has earned the L1 advanced engine performance certification. He is also a graduate of Colorado State University and belongs to the Automotive Service Association (ASA) and the Society of Automotive Engineers (SAE).