Vehicles:

• Ford: 2003 Crown Victoria

• Mercury: 2003 Grand Marquis

Issue:

Some 2003 Crown Victoria/Grand Marquis base vehicles with steel wheels or vehicles equipped with the handling package may appear to have a harsh ride in the front end of the vehicle. This may be caused by the front springs.

Action:

Replace the existing springs with revised springs. The revised springs provide a higher ride height at curb and reduce the possibility of the front being too low. Refer to the following service procedure for details.

Note: Do not install revised springs on vehicles other than base vehicles with steel wheels or vehicles equipped with the handling package.

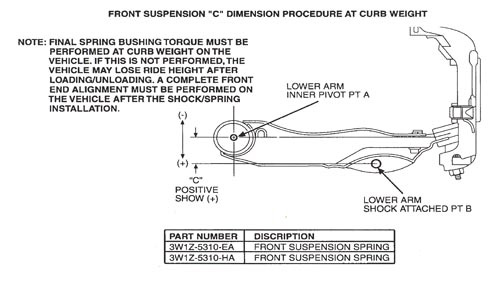

1. Verify that the vehicle is low in the front by measuring the ride height “C” dimension, at curb height. At curb condition the vehicle should have full fluids, but no additional weight of passengers or luggage.

2. To properly measure ride height: Pull the vehicle onto an alignment rack, set the transmission in park, and do not set the parking brake. Pull the pins constraining the wheel pads then bounce the vehicle four times with amplitude of two inches per bounce to neutralize the suspension. If you do not have an alignment rack with floating wheel pads, you must roll the vehicle (forward or backward) four feet before you bounce the vehicle. Measure the ride heights as defined in the following steps.

For front ride heights:

a. Measure the distance from the lower control arm (LCA) inner pivot points “A” (bolt center) to the ground.

b. Measure the distance from the shock attachment “B” (bolt center) to the ground.

c. Subtract measurement “B” from “A” and the front ride height should be at a minimum of 60 mm (See Figure 1).

3. If the vehicle is below 63mm, but above 57mm, remove existing springs and replace with 3W1Z-5310-EA. Refer to Section 204-01 of the Workshop Manual for replacement procedures.

4. If the vehicle is below 57mm, remove existing springs and replace with 3W1Z-5310-HA. Refer to Section 204-01 of the Workshop Manual for replacement procedures.

Note: Final spring bushing torque must be performed at curb weight on the vehicle. If this is not performed, the vehicle may lose ride height after loading/unloading. A complete front end alignment must be performed on the vehicle after the shock/spring installation.

Technical service bulletin courtesy of Mitchell 1.

For additional information, visit www.mitchell1.com.