A vehicle lift is the centerpiece of most service and repair bays. As an integral part of vehicle maintenance and repair tasks, it is used more times every day than just about any other piece of shop equipment. There is a general perception that all lifts are pretty much the same, differentiated only by price. This can be a dangerous mindset.

A vehicle lift is the centerpiece of most service and repair bays. As an integral part of vehicle maintenance and repair tasks, it is used more times every day than just about any other piece of shop equipment. There is a general perception that all lifts are pretty much the same, differentiated only by price. This can be a dangerous mindset.

“Unlike other shop equipment, if a lift fails, a technician can be seriously injured,” says Gary Kennon, chairman of the board of the Automotive Lift Institute (ALI) and president of lift manufacturer Rotary. “It is imperative that shop owners, managers and dealer principals consider a number of factors including safety when deciding which lifts to buy.”

With a foremost focus on safety, Rotary offers the following four tips for choosing vehicle lifts.

1. Look for the gold “ALI Certified/Validated by ETL” label. This label indicates that the lift has been tested and certified to meet ANSI/ALI ALCTV-1998 safety standards. Only lifts that have passed testing by a Nationally Recognized Testing Laboratory (NRTL), can display this label. Without ALI certification, buyers have no third-party assurances that a lift meets accepted industry safety standards. Note that certification is for an individual model of lift, not the lift manufacturer. If a manufacturer has one ALI-certified lift, that does not mean that all of its lifts are certified.

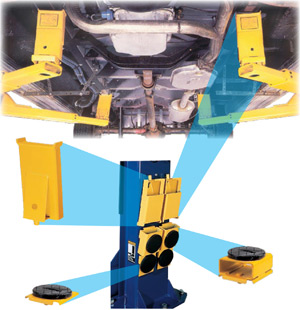

2. Physically inspect the lift you’re considering. Look at the quality of construction. Do the welds appear thick and uniform? Are the steel components clean or are they covered with weld splatter? Do the inner arms fit snugly in the outer arms? Check for safety systems, including mechanical safety locks, arm restraints where fine adjustment is possible and a spotting dish (for frame-engaging lifts) to ensure that the vehicle is positioned properly.

3. Consider the manufacturer and its manufacturing/testing processes. How much experience does the company have engineering and building vehicle lifts? What is its reputation? Was the lift built in North America or offshore? If it was built offshore, who designed it? Ask if each lift is individually tested to meet ALI safety standards before it is shipped to the customer. Are factory-trained installers and technicians available, or are you on your own for installation and maintenance? Are the operating instructions that come with the lift clear and easy to understand? Does the manufacturer stand behind its lifts with a strong warranty? How much liability insurance does the manufacturer carry? Is the manufacturer certified to ISO 9001 quality standards?

4. Remember that you get what you pay for. If a lift seems unusually inexpensive, ask why other lifts cost more. Like with any tool or piece of equipment, a cheap lift will generally cost more in the long run because of excessive downtime and repair costs. Ask where replacement parts will come from, how quickly they’ll arrive and who will install them. Ask what is included in the price: accessories, shipping, professional installation? What does the manufacturer do to ensure product quality and consistency? How is the lift packaged for shipping?

Once a lift is installed, technicians also have responsibility for their own safety. Careless vehicle spotting and lift operation can lead to dangerous situations even when using ALI-certified lifts. ALI offers a variety of lift safety materials, including the following advice. Visit the organization’s website at www.autolift.org for more.

- Inspect your lift daily. Never operate it if it malfunctions or if it has broken or damaged parts.

- Operating controls are designed to close when released. Don’t block open or override them.

- Never overload your lift. The manufacturer’s rated capacity is shown on a nameplate affixed to the lift.

- Only trained and authorized personnel should position the vehicle and operate the lift.

- Load a vehicle lift carefully. Position lift supports to contact at the vehicle manufacturer’s recommended lifting points. If you are working under the vehicle, the lift should be raised high enough for the lift’s locking device to engage.

For more information about any Rotary Lift products or services, contact your local Rotary distributor, call Rotary at (800) 640-5438 or visit www.rotarylift.com.