Ball Joints: Greasable And Sealed

One of the most frequent questions from customers is in regards to the availability of “greasable” chassis parts. Sealed-for-life components are very common at the OEM level, but many technicians have a definite preference for aftermarket greasable components. This poses the question: If greasable suspension joints are so popular, why don’t many modern suspensions have grease fittings anymore?

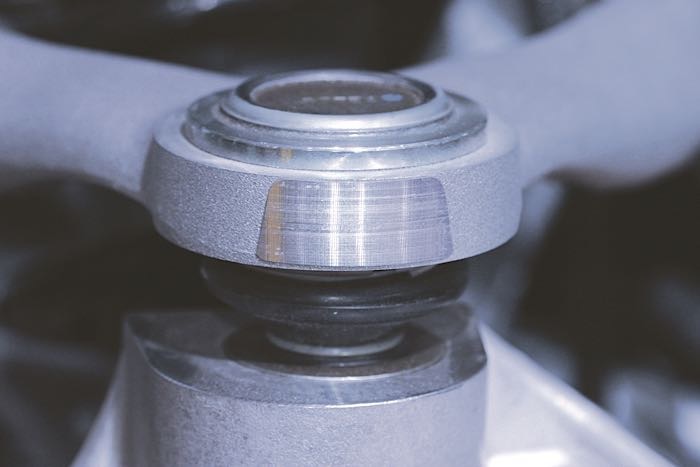

MOOG Introduces High-Strength Ball Joint For Compression-Loaded Suspension Systems

Federal-Mogul Motorparts’ MOOG Steering and Suspension brand has introduced a high-strength replacement load-carrying ball joint for a broad range of late-model vehicles equipped with compression-loaded suspension systems. The company says this exclusive new MOOG Problem Solver ball joint is visually different from conventional ball joints as a result of its pre-installed patent-pending, low-profile integral dust

Mazda issues recall due to ball joint corrosion

Mazda North American Operations notified the National Highway Traffic Safety Administration (NHTSA) that it was issuing a safety recall for certain 2007-14 model year CX-9 vehicles manufactured from Oct. 24, 2006 to Dec. 28, 2013. According to the recall acknowledgment, the vehicles in question may have front suspension ball joints that are susceptible to corrosion

Mevotech TTX Terrain Tough Ball Joints Category Expanding To Address Escalating Demand

Mevotech’s Canadian engineering team has designed a new line of high-performance ball joints using patented technology that the company says significantly extends service life. The new line was created to address ball joint failure issues in extreme duty applications. Engineered specifically to withstand the demands of extreme duty applications and extended maintenance cycles, TTX Terrain Tough

Measuring Ball Joint Wear

Detecting and measuring wear in a ball joint is critical to ensuring the safety of a vehicle. When a ball joint fails, the driver loses control of the vehicle. This can result in damage not only to the suspension, but also the axle shafts, brakes and even the body.

Why Do Ball Joints, Tie Rods And Control Arms Wear Out?

The ball and socket joint has been around on animals and humans for millennia. This simple design has been used on vehicles since the turn of the century because it works. But, just like our hip joints, ball and socket joints, like ball joints, tie rods and sway bar links, wear out.

Torque-To-Yield Suspension Components (Ball Joints, Tie Rods And Control Arms)

Always make sure to check the service information to get the right torque for a suspension component no matter what type of fastener. If you see an initial torque spec along with an angle in degrees, it is a torque-to-yield (TTY) fastener. TTY ball joint and tie-rod studs have two advantages. First, they can weigh less and still apply the same clamping loads. Second, the clamping loads are more consistent and controllable.

Tech Tip: Solving Lower Ball Joint Removal and Installation Issues

When installing a replacement ball joint in these applications, technicians may note that the new ball joint may not fit tight in the opening of the lower control arm.

Solving Lower Ball Joint Removal and Installation Issues

When installing a replacement ball joint in certain applications, technicians may note that the new ball joint may not fit tight in the opening of the lower control arm. Affected vehicles are: Ford Expedition, Explorer, Explorer Sport Trac, F-150, F-150 Heritage, F-250, Ranger, Lincoln Navigator, Mazda B2300, B3000 and Mercury Mountaineer.

Why do Automotive Ball Joints, Tie Rods and Suspension Links Wear Out?

The ball and socket joint has been around on animals and humans for millennia. This simple design has been used on vehicles since the turn of the century because it works. But, just like our hip joints, ball and socket joints like ball joints, tie-rods and sway bar links wear out.