I learned a little about life, a little about respect and a little about people and how you deal with all different types of personalities. I can also run a broom with the best of ’em (education does not come cheap). Looking back, it was the best education I could have ever hoped for.

I was soon getting calls from local 6-volt vehicle owners wanting me to share my expertise. Knowing full well (from hanging around the local garages) that “anyone 20 miles from home” is considered an expert, and that advice is only worth “what you pay for it,” I decided to jump right in and start helping those 6-volt vehicle owners.

In the beginning the rules were simple: “Just make my old car/truck reliable enough so I can drive it back and forth to work on a daily basis” or “I want to be able to drive my antique car to a car show without it overheating and the battery going dead.”

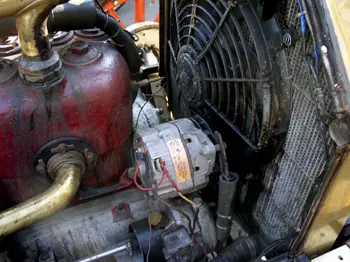

By this time I was shoulder deep in 6-volt electrical systems. I decided to apply modern technology in reverse and build a 6-volt alternator. I was convinced that was the way to improve the reliability of the 6-volt electrical systems without having to upgrade them to 12-volts. I got little support for “that dumb idea” and often heard “if that idea was a good one, they would have already done that” and “you’re just wasting your time and mine.”

But I marched on despite my lack of support. I knew 6-volt electrical systems needed help and I was convinced I was just the guy who could deliver it.

Not having an engineering degree does have its advantages — your thought process is wide open with no restrictions and no rules. But I quickly learned that things are not always as simple as they first appear. My final working 6-volt alternator design proved to be a lot more expensive than I could have imagined.

In the spring of 1983, my 1951 Chevrolet Pickup became the test vehicle for the new 6-volt alternator. I drove it every day and night for a full year, winter and summer. It worked. I never had another dead battery and for the first time, I could see both sides of the driveway at the same time.

In 1985, I began manufacturing and selling my 6-volt alternators locally…with good success. A year later I offered them statewide and sold the 200th alternator by Thanksgiving.

In 1987, I started Fifth Avenue Antique Auto Parts to manufacture and market my new 6-volt alternator invention nationwide. Little did I know that marketing a 6-volt alternator would prove to be just as

difficult as inventing it in the first place.

I had little money for a national advertising campaign and no track record for the alternator except local installations. Nevertheless, I was convinced that I was ready for the big time. I found the solution to my problem in the Great American Race.

The Great American Race was a cross-country race in which pre-1942 vehicles were driven 4,500 miles across the United States in two weeks’ time. I decided the Great American Race would be a good way to establish a track record for my 6-volt alternator. If I could prove the alternator could go the distance and do what the Great Race entrants expected it to do, then I would have the proven track record I needed.

I planned on installing the first one on a Ford or Chevrolet application. So I began knocking on doors presenting my best sales pitch. Because 6-volt alternators didn’t exist until I came along, it was a pretty tough sell. The first one ended up on a 1936 Cord owned by Bud Melby of Seattle, WA. (I had never even heard of a Cord automobile until then.)

Turns out that besides the usual electrical load, the Cord transmission used electrical solenoids to shift the car, which also happened to be front-wheel drive. Low voltage in the battery often caused the transmission to “be stuck in a gear.” It was common practice for the 6-volt battery to be “swapped” out at noon each day during the race. I finally found my first Great Race customer. Why couldn’t the first one be a simple Ford or Chevy application?

Literally, the eyes of 100 Great Race entrants were focused on the 1936 Cord and that 6-volt alternator. One of the most vocal doubters said (what I’d heard before), “If the idea of a 6-volt alternator was such a good one, somebody would have done it a long time ago.” I doubt that him being from New York had anything to do with it, but being from Kansas, I was more than a little intimidated.

The alternator passed the test with flying colors. The doubter, Howard Sharp (seen driving above), became a believer and a very vocal one. He immediately ordered one for his 1932 Dodge Sport Roadster. He went on to win the Great American Race in 1993. He took home $30,000 and a brand new Buick Roadmaster.

Some 20 years later, Howard is still my best advertising spokesman.

Howard moved up into the Great American Race expert championship class and entered a 1911 Velie. I began sponsoring him and his Velie in the Great Race (as it is now known) starting in 1994. It was a challenge to prepare what was often the oldest car entered into the race.

Every year Howard got close to winning but the routes were a difficult challenge with trips up over Pikes Peak and across deserts in California. It was almost more that you should expect from a car 90-plus years old!

But in 2011, Howard and his son Douglas won the Great Race driving the oldest car entered in the race, with the Velie turning 100 years old! There is more than a little satisfaction in being a part of that. To me it represented a validation — that I “got it right.”

I have had 25-plus years of hands-on experience preparing antique vehicles for events like the Great Race. What I have learned I have applied to the average customer’s antique vehicle to make it more reliable and fun to drive.

I was thinking this was settling in to be the norm. Then in 2009 comes the customer from Switzerland telling me he has entered the Peking to Paris Motorcar Challenge. It will be a 10,000-mile route across the Gobi desert and he is driving a 1950 Plymouth. “Word is you are good at preparing antique vehicles for long distance travel. Will you help me prepare?”

Oh, what happened to the days when they just wanted to drive a hundred miles to a car show…?

He has prepared vehicles for movie studios, The Great Race, the 10,000-mile “Peking to Paris Motor Car Challenge” and other similar events.

Rundle, an author of six automotive technical books, has spent 20-plus years solving electrical, cooling and fuel-related problems on all types of antique and classic vehicles.