Colorado High School Students Get By With a Little Help From Their Friends

Starting with 16 students, Sprague announced to the very first Wheat Ridge STEM Engineering Team that they were going to build a car and compete in the Shell Eco-marathon, which challenges student teams across the globe to design, build, test and drive ultra-energy-efficient vehicles.

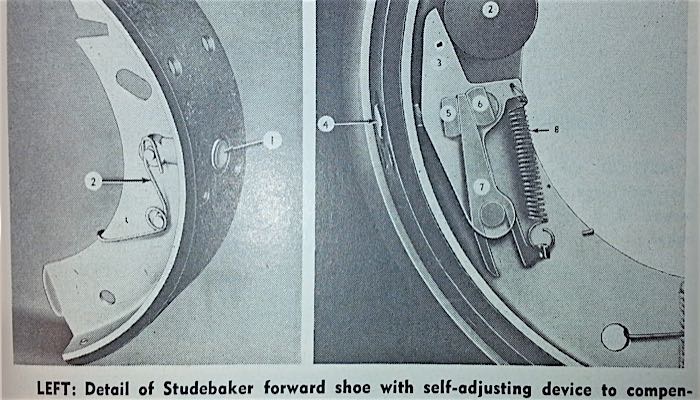

BRAKELIGHT: September 1949

For the past 50 years, self-adjusting drum brakes have been standard equipment on almost all vehicles. Before the self adjuster, some drivers had to visit shops every 1,500 to 2,000 miles to have their brakes adjusted.

Cold And Flu: Prepare Your Shop For The Season

While having to deal with the onslaught of symptoms is reason enough to protect yourself from cold and flu germs, the cost of missing work due to an illness could be even greater.

Brake Pad Copper Update

Like it or not, recent mandates limiting the concentration of copper allowed in brake pads could be our generation’s asbestos. We are just at the start of what could be a painful, but necessary, process that will impact your shop and the environment in a positive way – even if you do not live on the West Coast.

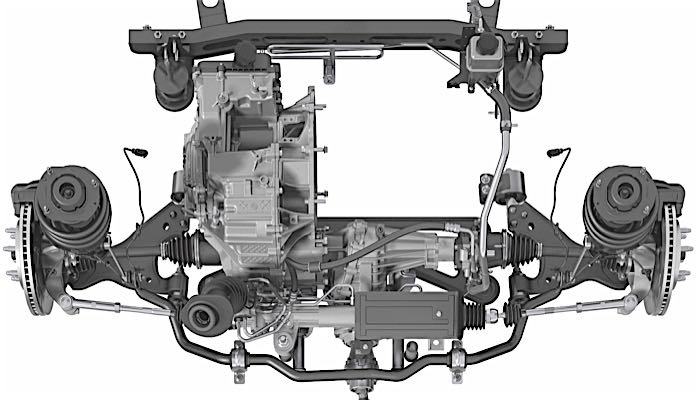

Scion FR-S And Subaru BR-Z Alignment Service

The Scion FR-S and Subaru BR-Z are essentially the same vehicle except for some badging and styling touches. The rear-wheel-drive platform has a Subaru engine and rear suspension. The BR-Z is the the only Subaru in the lineup without all wheel drive, and the only Scion that sends power to the rear, respectively.

How Education And Equipment Can Help Manage Your Car Quota

Every day while driving to work, I’ll pass numerous shops that seem to have the same cars sitting in front of their bays day after day. They move them around a bit, you know, kind of like shuffling chess pieces or something, but they never seem to leave.

TPMS And Custom Rims

When a new wheel and tire package is fitted, the TPMS and sensor should be considered along with the looks. The sensors can’t be sacrificed if they don’t fit the new rims.

Proper Rotor Service Prevents Comebacks

Everybody who works on brakes knows what brake rotors do. They provide a friction surface for the disc brake pads to rub against when the brakes are applied. The friction created by the pads rubbing against the rotor generates heat and brings the vehicle to a stop.

Transmission Line Replacement

Transmission fluid likes to be at a constant temperature. If it is too hot or too cold for too long, the performance can fluctuate and potentially cause damage to the transmission.

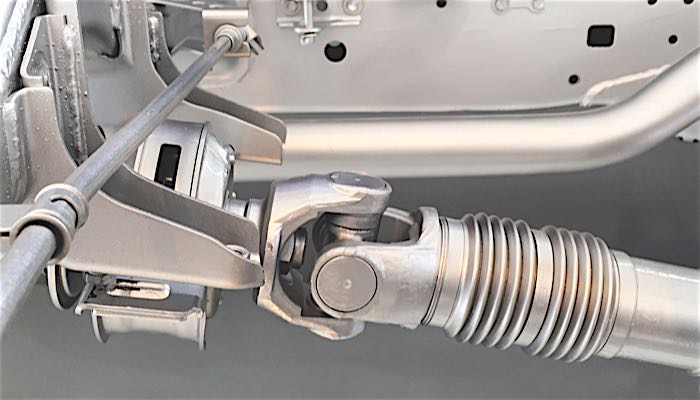

Driveshaft Diagnostics and Service

Driveshaft problems can be spotted from the moment you put the vehicle in gear to pull it into a bay. As the power is transmitted from the transmission to the rear axle, the slack from worn or damaged components is taken up, resulting in a sudden crunch or pop.

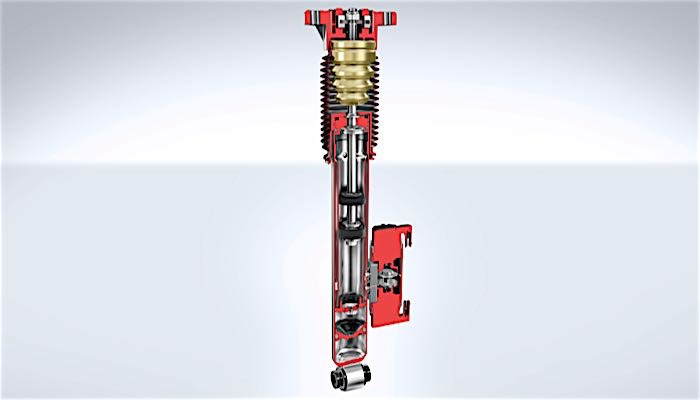

Electronically Adjustable Dampener Diagnosis

Modern suspension systems can read the road and the driver’s intentions to help select the correct amount of dampening force. These systems see the vehicle dynamics through accelerometers and Hall-effect sensors, and they can change settings in milliseconds. Some can even detect potholes and dial up the rebound so the wheel does not drop to the bottom.

Telematics In The Aftermarket: Great Opportunity Or Waste Of Time?

OE-implemented telematics have the potential to change how vehicles are engineered. If engineers have access to vehicles in the field, they might be able to engineer a better product. Another benefit of OE telematics systems is the ability to update modules without the customer having to return to the dealership.