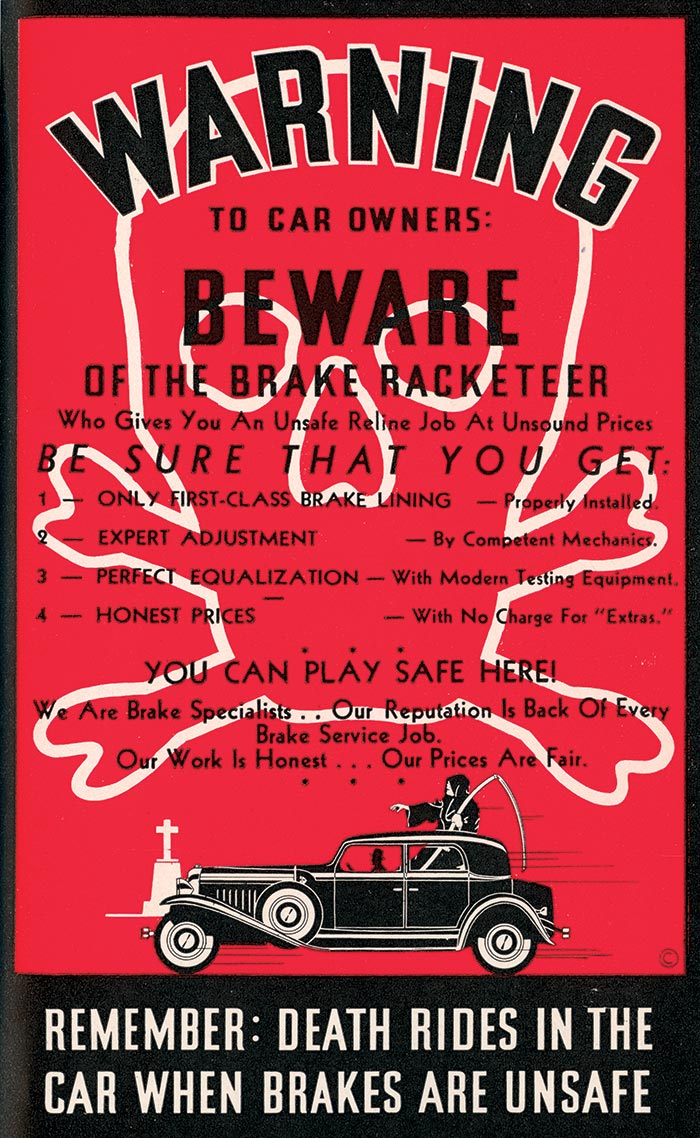

In the 1930s, brake services like relining and adjustments were performed more often than oil changes. Most vehicles with mechanical brakes required adjustment every 1,000 miles to make sure they stopped straight or even stop at all. Shops were being forced to compete with people who performed brake repairs in backyards and at the side of the road. Most of these shops were nothing more than a hand-painted sign and a box of tools. Today, shops face the same challenge, but the sign has been replaced with a Craigslist ad and a smartphone. Brake & Front End published this poster in 1932 for shops to put in their windows so customers would be warned of brake racketeers who promised brake services at unsound prices.

In 1932, most vehicles with mechanical brakes required a procedure called equalization since self adjusting brakes were not yet invented. The procedure involved adjusting the space of linings to drum and then adjusting the rods that connected to an equalizing bar that acted as a mechanical proportioning valve. If the adjustment was not performed correctly, the wheels could lock and cause the car to pull violently when the brakes were applied.