By Tom Purser, ALLDATA Editor and Jeff Webster, ALLDATA Technical writer

Some Volvo owners (2001-2004 S60, V70, V70XC and 1999-2004 S80) may complain about constant vibrations and humming while braking (not from ABS modulation). Variations in the thickness of the front brake discs may cause a pulsing pedal or erratic deceleration during normal braking just before coming to a complete stop. Speeds at which the symptoms are most evident are 55-70 MPH. Steering wheel vibrations in the bodywork will start at 5-25 MPH with humming/vibrations at 54 Hz from the rear axle.

This Tech Tip describes how to diagnose and repair the problem. It is primarily intended to identify whether the vibrations are coming from the front or rear. The operation requires Measuring tool kit – P/N 999 5418 and Holder dial test indicator – P/N 999 5773. Review safety procedures in ALLDATA Repair before beginning.

This Tech Tip describes how to diagnose and repair the problem. It is primarily intended to identify whether the vibrations are coming from the front or rear. The operation requires Measuring tool kit – P/N 999 5418 and Holder dial test indicator – P/N 999 5773. Review safety procedures in ALLDATA Repair before beginning.

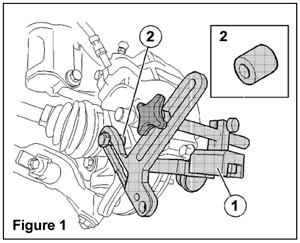

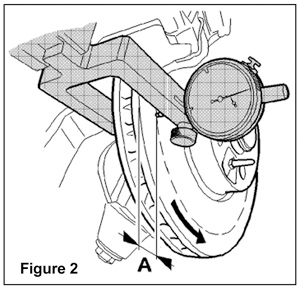

1. Check and adjust brake vibrations by installing the special tool on the front brake discs. Remove the lower screw from the brake caliper bracket. Install the Measuring Tool and Holder as illustrated in Figure 1. Use a screw and a spacer sleeve (2). Adjust holder so that it does not lie against the shield or caliper. Make sure the measuring tips are tight. Dimension (A) = 20 mm from edge of brake disc (Figure 2).

Caution! Turn the brake disc downward at the front edge (counter clockwise for the left-hand side and clockwise for the right-hand side) so that any play in the holder (P/N 999 5773) does not affect the measurement result. Maximum permitted variation in thickness (DTV) is 0.014 mm in front and 0.010 mm for the rear.

Caution! Turn the brake disc downward at the front edge (counter clockwise for the left-hand side and clockwise for the right-hand side) so that any play in the holder (P/N 999 5773) does not affect the measurement result. Maximum permitted variation in thickness (DTV) is 0.014 mm in front and 0.010 mm for the rear.

2. Measure one of the front sides of the disc. If the variation in thickness is greater than the given max value, replace both front brake discs and pads and continue with Step 3 below. If the variation in thickness is less than the given max value, take measurements from the other front disc.

• If the variation in thickness is greater than the given max value, replace both front brake discs and pads. Continue with Step 3. If the variation in thickness is less than the given max value, continue with Step 3.

3. Measuring the rear brake discs. Install Measuring Tool and Holder and take measurements from one of the rear discs. If the variation in thickness is greater than the given max value, replace both rear discs and pads. If the variation in thickness is less than the given max value, take measurements from the other rear disc. If the variation in thickness is greater than the given max value, replace both rear discs and pads. If the variation in thickness is less than the given max value, the repair is complete.

Courtesy of Alldata.

For additional information, visit www.alldata.com.