If a customer indicates that a light ticking or humming noise can be heard coming from the blower motor (see affected vehicles) when the motor is run at low fan speeds (speed 1 or 2), a noise-reducing blower motor is available. The noise may be very slight and, at times, difficult to hear.

Affected Vehicles:

• 1996-2001 Pathfinder (R50);

• 1995-’99 Maxima (A32);

• 2000-’01 Maxima (A33) with automatic heater/air conditioner controls.

Service Procedure:

- Run the blower motor at low fan speed (speed 1 or 2) and evaluate the noise. Decide which category the noise falls under:

- Loud rattle, clatter, jolt or flap: go to the procedure for blower case cleaning.

- Light ticking or humming noise: complete the following steps to install a new blower motor cover.

-

Remove the instrument panel lower cover (if equipped).

Remove the instrument panel lower cover (if equipped). - Disconnect the blower motor harness connector.

- Clean the blower motor housing to ensure adhesive strips on the back of the blower motor cover will stick (standard window cleaner can be used). Note: Be sure to remove all residual film from the blower motor housing that may have been left by cleaning.

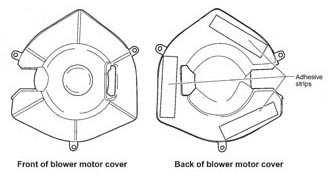

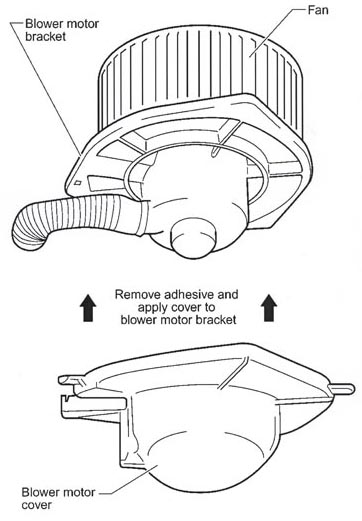

- Peel the protective coverings from the adhesive strips on the blower motor cover. See Fig. 1.

-

Install the blower motor cover onto the motor bracket. See Fig. 2.

Install the blower motor cover onto the motor bracket. See Fig. 2. - Reconnect the blower motor harness connector.

- Reattach the instrument panel lower cover (if equipped).

- Run the blower motor at low fan speed. Confirm that the blower motor is working properly and the noise is eliminated or reduced to an acceptable level.

Blower Case Cleaning:

- Remove the blower motor unit from the blower case.

- Remove all foreign material from the case.

- Reinstall the blower motor unit.

Technical service bulletin courtesy of Mitchell 1.

For more information on Mitchell 1 products and services, automotive professionals can log onto the company’s website at www.mitchell1.com.