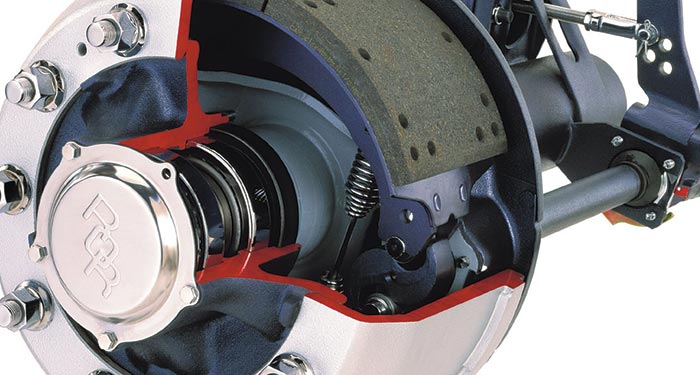

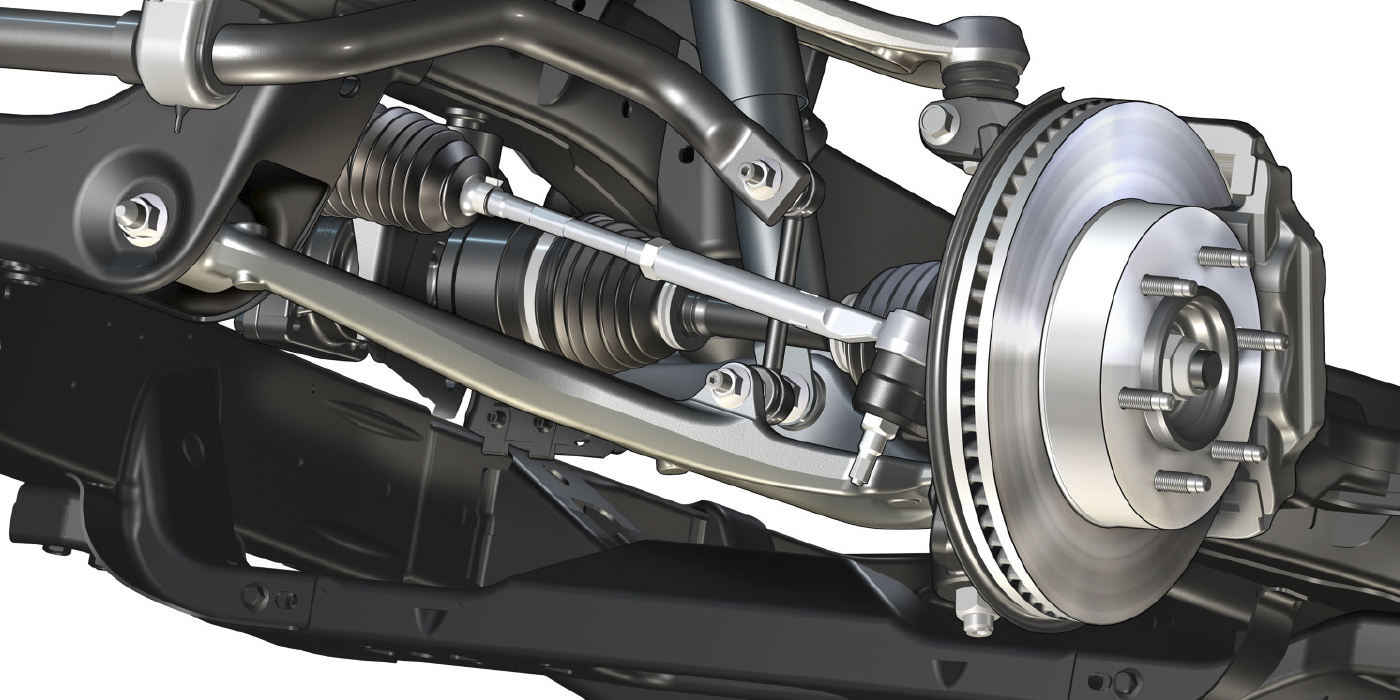

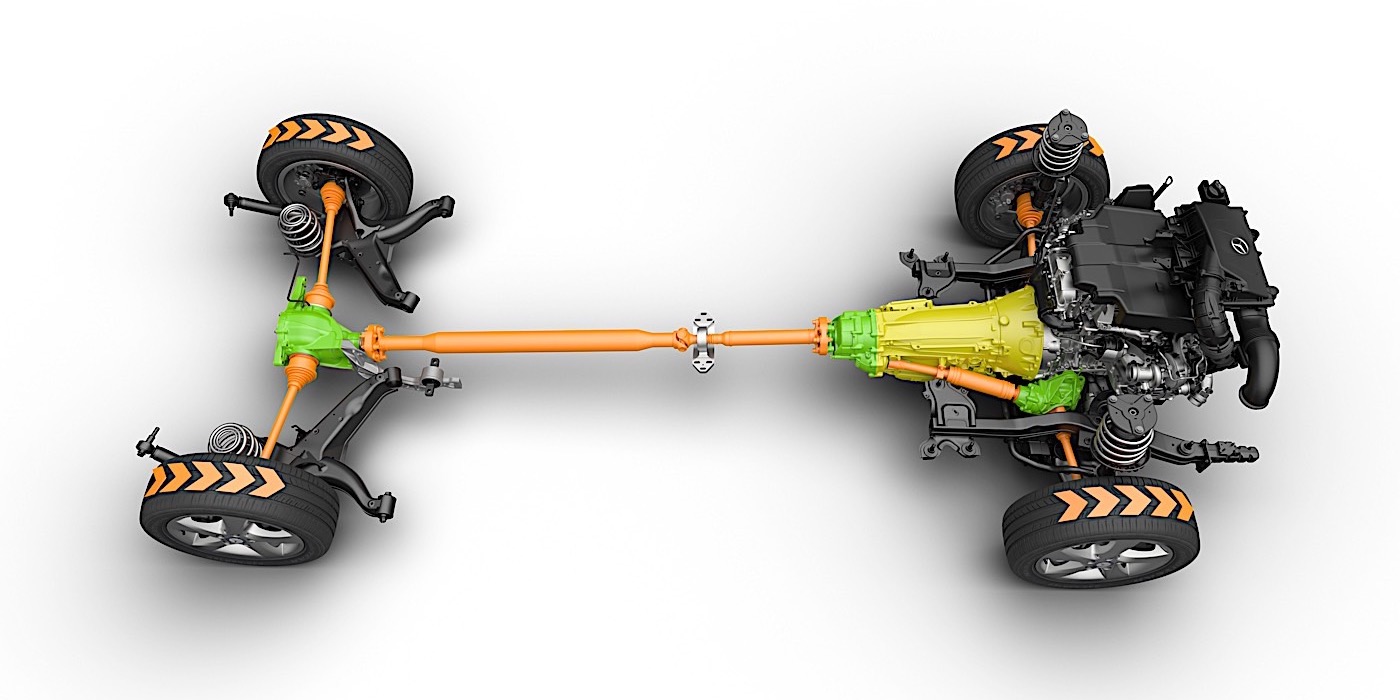

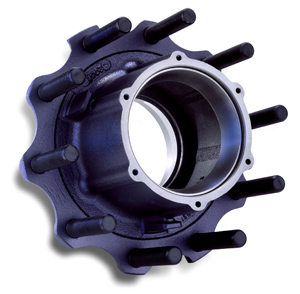

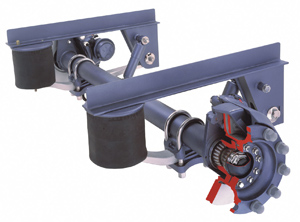

The trucking industry has a confusing term it uses called “wheel ends.” The term covers brakes, hubcaps, tires, seals, lubricant, bearings and spindle nuts. A 16 wheeler truck can mean more  than 10 wheel ends units that can go bad. While the scale of these vehicles is rather large, the basics are the same when it comes wheel bearing diagnostics and maintenance.

than 10 wheel ends units that can go bad. While the scale of these vehicles is rather large, the basics are the same when it comes wheel bearing diagnostics and maintenance.

Detection of wheel-end problems before they cause downtime could save a heavy-duty trucking customer from expensive emergency roadside towing and repairs. The driver’s observation and your visual inspection is your first tool in detecting a wheel-end or wheel-bearing problem. Bearing damage may have already begun if you notice any of the following symptoms:

• Uneven tire wear;

• Hubcap (too hot to touch);

• Vibration, wobble or noise;

• Smoke or a burning smell at wheel end; or

• Abnormal brake performance.

In selecting the best maintenance intervals for your fleet, first look at the maintenance schedules and service life experiences for your truck/trailer wheel ends. If a component fails or re-quires unscheduled service, a shorter inspection interval may be required. If a component fails too soon, it is a critical to understand why it failed to prevent failures on other vehicles in the fleet.

In selecting the best maintenance intervals for your fleet, first look at the maintenance schedules and service life experiences for your truck/trailer wheel ends. If a component fails or re-quires unscheduled service, a shorter inspection interval may be required. If a component fails too soon, it is a critical to understand why it failed to prevent failures on other vehicles in the fleet.

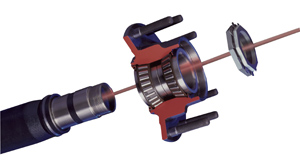

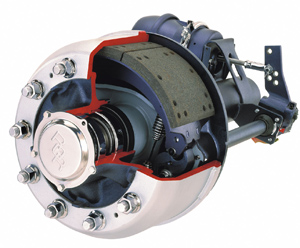

One term you may here a lot is “bearing preload.” In the case of truck wheel ends, pay very close attention. The proper preload procedure can mean the difference between a the wheel staying on the truck and a 700-lb. wrecking ball going 60 mph.

Preload describes a bearing setting that does not have any internal axial clearance in the bearing system. Simply stated, preload represents a tight bearing setting, whereas endplay represents a loose setting.

To date, there isn’t anything available that will confirm that the fastener is providing the correct preload setting. Be aware that if you are attempting to set preload in a traditional wheel end, you are depending on the quality of all the components and the skill of the technician to get it correct every time.

The benefits of a light and controlled preload bearing setting are negated if bearing preload force is excessive. Excessive preload can cause high operating temperatures, reduced lubricant life, reduced seal life and premature bearing damage. Bearing lock-up and/or wheel end separation may occur if the preload force is excessive.

The benefits of a light and controlled preload bearing setting are negated if bearing preload force is excessive. Excessive preload can cause high operating temperatures, reduced lubricant life, reduced seal life and premature bearing damage. Bearing lock-up and/or wheel end separation may occur if the preload force is excessive.

The most important thing to remember about pre-load is to follow the bearing manufacturer’s instructions to the letter. If the instructions tell you check end play with a dial indicator, you had better do it.

The most critical component of a heavy-duty wheel end is the softest part, the seal. The seal stands between the elements and the bearing surfaces and is engineered to take a lot of abuse. Also, the seals are engineered to give the least amount of resistance to increase fuel economy.

When replacing the seal on a wheel end, there are two things to remember. First, most seals come pre-lubricated from the factory. The grease will be between the primary and dirt lips. Second, never try to improve a seal by adding silicone sealers. The hardened material will prevent the lips of the seal from following the surfaces of the axle as it rotates under load.

To ensure wheel ends are protected over the long haul, it’s important to begin by selecting a proper grease to protect the hub. A high-quality hub lubricant helps avoid costly repairs by providing oxidation resistance, protection against corrosion and a defense against wear.

By performing regular, proper hub lubrication service, fleet managers can ensure that equipment isn’t losing valuable operating hours. Bearings are lubricated with fluids or greases. Grease offers the advantage of reducing leakage into the environment. Citgo Petroleum Corporation’s heavy-duty division offers the following key hub lubrication procedure tips to ensure lasting protection of hubs.

By performing regular, proper hub lubrication service, fleet managers can ensure that equipment isn’t losing valuable operating hours. Bearings are lubricated with fluids or greases. Grease offers the advantage of reducing leakage into the environment. Citgo Petroleum Corporation’s heavy-duty division offers the following key hub lubrication procedure tips to ensure lasting protection of hubs.

- Remove the hubcap and drain the existing hub oil. Collect the used oil and wash the bearings and other hub components with solvent to remove contaminants.

- Pressure pack the wheel bearings with hub grease using a hand-operated or air-powered pump with a bearing adapter.

- Apply a thin coat of hub grease inside the wheel assembly to prevent rust and corrosion.

- Install the inner bearing and new seal (making sure to follow the manufacturer’s recommended procedures).

- Spread a thin coating of hub grease where the seal meets the wear ring, after putting the bearing and seal in place.

- Use a wheel dolly to reinstall the wheel assembly back onto the axle. After the wheel is in place, use a pump to fill the hub cavity with hub grease to about 50 percent capacity.

- Pack the outer bearing, then install it on the spindle. Refer to manufacturer’s recommendations when tightening the nut assembly.

- Once the nut is in place, use a dial indicator to ensure there is no excess play in the wheel before the hubcap is reinstalled. This is vital because an improperly assembled hub can cause premature wear or create a future safety concern on the road.

- Apply a light coat of hub grease to the inside of the hubcap using care not to cover the vent hole. Bolt-on hubcap models should be torqued according to specifications and thread-on models should be coated with a thin layer of hub grease before being twisted into place.

Grease lubricants contain three substances: oil, a thickener base and additives. The oil lubricates. The thickener (base) holds the oil in place and releases it to provide the necessary lubrication. The thickener may be a simple or complex soap (lithium, calcium, aluminum, etc.), organic (polyurea) or inorganic (clay). The additives enhance the characteristics of the oil and thickener.

Extreme Pressure (EP) additives help prevent scoring, galling and welding of moving parts. Do not mix different types of greases, ArvinMeritor advises, because the possibility of incompatible greases may reduce their lubricating ability.

An important property of a grease is its dropping point, the temperature at which grease changes from a semi-solid state to a liquid. But, ArvinMeritor cautions, the operating temperature of a specific grease is not determined solely by its dropping point. Other properties, such as resistance to change in consistency and chemical deterioration at high temperatures also play a role.