Applied Vehicles: 2002-’03 Altima (L31) with QR25 and VQ35 engines and Sentra (B15) with QR25 engine; and 2000-’04 Sentra (B15) with QG18 engine.

If you confirm that an applied vehicle has DTC P0100/P0102/P1102 stored and may also exhibit a rough-running engine, slight engine speed variation while driving or low engine power, then take the following actions:

Actions:

• Remove any dust/dirt/debris from inside the air cleaner housing. This may help prevent another incident.

• Replace the sensor in the airflow meter housing with a new plug-in sensor part (for Altima/Sentra QR25 and VQ35 engines, P/N 22680-8J020; for 2000-’02 Sentra with QG18 engine, P/N 22680-5M020; and for 2003-’04 Sentra with QG18 engine, P/N 22680-8U320).

• Install a new air filter element (P/N 16546-0Z000).

Service Procedure:

-

Remove the ducting from the airflow meter housing.

Remove the ducting from the airflow meter housing. - Pull off the connector from the airflow meter.

- Remove the air cleaner cover with the airflow meter attached.

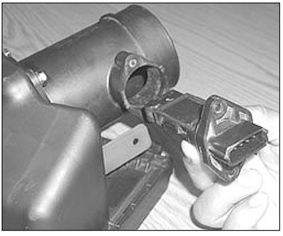

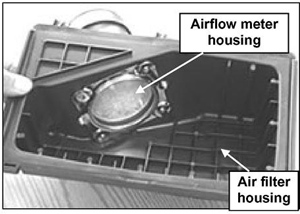

- Remove the sensor from the airflow meter assembly housing. See Figure 1. You will do this by removing the two torx screws, which could be either a standard T20 torx or a tamper-resistant torx plus 25IPR. For removal of the 25IPR, you need Essential Tool J47010 Tamper-Resistant Plus 25IPR Bit.

- Remove the air filter element.

- Wipe out the inside of the airflow meter housing with a clean shop rag. See Figure 2.

-

Using low-pressure compressed air or a shop vacuum, clean out all dust/dirt/debris from inside both halves of the air filter housing, and inside of the airflow meter housing. Caution: Cover the ducting from the throttle body with a clean shop towel or other method so that no dirt or debris can enter the engine intake manifold. Make sure all dust/dirt/debris is removed from the air filter housing in order to prevent a repeat incident.

Using low-pressure compressed air or a shop vacuum, clean out all dust/dirt/debris from inside both halves of the air filter housing, and inside of the airflow meter housing. Caution: Cover the ducting from the throttle body with a clean shop towel or other method so that no dirt or debris can enter the engine intake manifold. Make sure all dust/dirt/debris is removed from the air filter housing in order to prevent a repeat incident. - Install the new plug-in sensor into the old airflow meter housing. Do this by using the two new screws included with the sensor. Hand-tighten using the J47010 bit. Note: The sensor kit comes with two types of screws. You must put back in the same type of screw that you removed.

- Install a new replacement air filter element into the filter housing cover.

- Reassemble the air cleaner housing cover and the intake ducting back to the airflow meter housing.

- Install the connector back to the airflow meter.

- Use CONSULT-II to erase any stored DTCs.

- Verify the MIL stays off.

For additional information, visit www.mitchell1.com.

Technical service bulletin courtesy of Mitchell 1.