Wideband or Wide Range Air Fuel (WRAF) sensors don’t generate a voltage signal like common zirconia oxygen sensors. An ordinary oxygen sensor produces a voltage signal of 0.8 to 0.9 volts when the air/fuel mixture is rich, then drops to 0.3 volts or less when the air/fuel mixture goes lean. The transition is quick and abrupt, so the PCM has to keep track of the back-and-forth rich/lean transitions to estimate the average air/fuel mixture.

By comparison, a WRAF sensor produces a signal that corresponds to the exact air/fuel ratio. Engineers call this a “linear” output because it changes in a smooth, predictable fashion. If you compare the output graphs of an ordinary oxygen sensor versus a WRAF sensor, the differences are obvious.

The ordinary oxygen sensor signal voltage starts out high and remains high as long as the air/fuel mixture is rich. Then it drops suddenly when the mixture goes lean and stays low regardless of how much leaner the air/fuel mixture might become. The WRAF sensor signal starts out low and gradually increases its output as the air/fuel ratio gets progressively leaner. This allows the PCM to accurately monitor the exact air/fuel ratio, including extremely lean ratios (18:1 and higher) that are increasingly common on late-model, ultra-low emission engines.

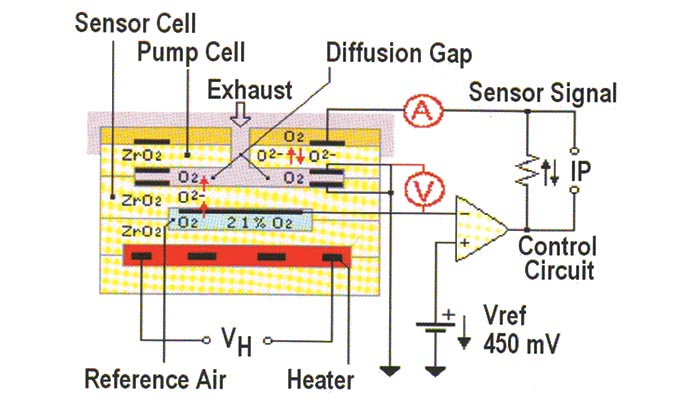

The WRAF sensor’s internal voltage output is converted by its built-in circuitry into a variable current signal that can travel in one of two directions (positive or negative). Think of it as a signal generator that can change polarity. The signal gradually increases in the positive direction when the air/fuel mixture becomes leaner.

At the “stoichiometric” or “lambda” point when the air/fuel mixture is perfectly balanced (14.7:1), the current flow stops and there is no current flow in either direction. When the air/fuel ratio becomes progressively richer, the current reverses course and flows in the negative direction.