The following tools and method should be used to remove the camshaft housing cover. This method prevents damage to the camshaft housing thrust bearing.

Tools:

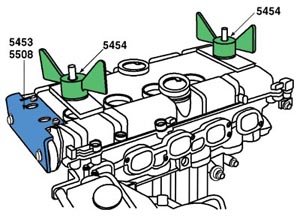

• 2-valve engines: 999 5508, 999 5454 (x2);

• 4-valve engines: 999 5453, 999 5454 (x2); and

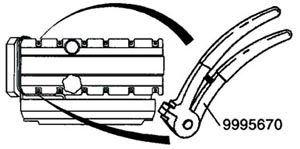

• 2/4 valve engines: 999 5670 (x1).

Service Procedure:

1. Install tool 999 5453 or 999 5508 to secure the front of the camshafts. See Fig. 1.

2. Install tool 999 5454, with a few millimeters of play, to the camshaft housing cover and remove all screws. See Fig. 1.

3. Disconnect the camshaft cover with pliers 999 5670 at the stop lugs. Start with cylinder 1 and work alternately backward. See Fig. 2.

4. Open and slacken off tool 999 5454 step by step so that parallel movement is ensured when removing the camshaft housing cover.

Technical service bulletin courtesy of Mitchell 1.

For more information on Mitchell 1 products and services, automotive professionals can log onto the company’s website at www.mitchell1.com.