We’ve heard about an oil cooler leak issue on some 2001-’04 GM 6.6L diesel engines. Can you fill us in more about this?

Answer: According to a technical bulletin on the JASPER Engines & Transmissions website, some engine specialists have reported an oil cooler leak on 2001-’04 GM 6.6L VIN 1 & 2 Duramax diesel engines used in pickup truck models.

The leak is caused by minor imperfections in the engine block machine surfaces at the oil cooler interface that may allow engine oil seepage past the oil cooler O-rings. To cure this problem, GM offers the following information:

1. Inspect for other oil leaks that may be perceived as an oil cooler leak. An oil leak from one of the main bearing cap side bolts may appear to be coming from the oil cooler.

2. If the oil cooler is leaking oil, remove the oil cooler from the engine. Use care to remove only the five bolts that hold the oil cooler to the engine block.

3. Remove the O-rings from the oil cooler and discard them.

4. Clean the mating surfaces of the engine block and the oil cooler.

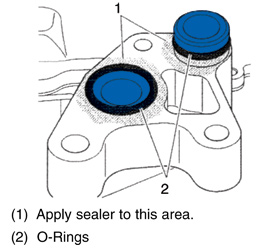

5. Install new O-rings (2) to the oil cooler (see Figure 1).

6. Apply sealant (P/N 97720043) to the oil cooler as shown in Figure 1. Do not apply sealant to the O-ring grooves on the oil cooler.

7. Install the oil cooler to the engine block. Torque five oil cooler assembly bolts to 18 ft.-lbs.

8. Allow the vehicle to sit for eight hours at room temperature to allow the sealant to fully cure before initial startup.

Source: JASPER Engines & Transmissions.

For information on products offered by Jasper Engines & Transmissions, call (800) 827-7455, or log onto www.jasperengines.com.