A musty odor may be emitted from the air conditioning system of some vehicles that are usually operated in areas with high temperature and humidity. It’s most noticeable when the air conditioner is first turned on after the vehicle has been parked for several hours.

The odor could result from one or more of the following conditions:

1. Blockage of the evaporator housing drain pipe, resulting in a buildup of condensate.

2. Microbial growth in the evaporator, arising from dampness in the evaporator housing where the cooling airflow is dehumidified.

To address excessive air conditioning evaporator odor, check the evaporator housing drain pipe for blockage. If no problems are found, the evaporator and housing should be cleaned and disinfected using the following service procedure.

While this procedure may be used on any Toyota vehicle, specific details for the 1997-and-older SXV/VCV10 Camry follow.Caution: Wear safety glasses, protective mask and gloves while working with the freshener.

Service Procedure:

1. Parts removal.

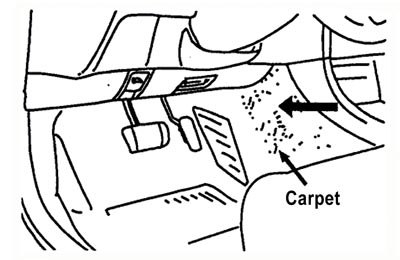

a. Pull down the carpet from the center console as indicated by the bigger arrow in Fig. 1.

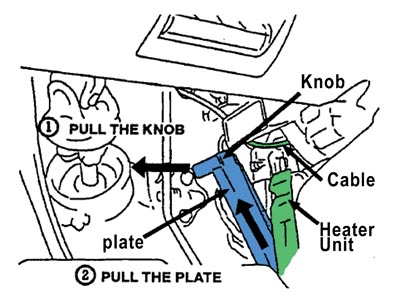

b. Remove the plate on the side of the heater unit using steps (1) and (2), indicated with bigger arrows to show direction in Fig. 2.

Caution: Do not bend the cable; the plate will be reused.

c. Remove the blower resistor.

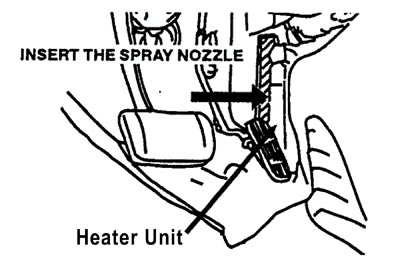

2. To clean the evaporator, follow the general procedures at the beginning of this bulletin. Also see Fig. 3.

3. Parts reinstallation.

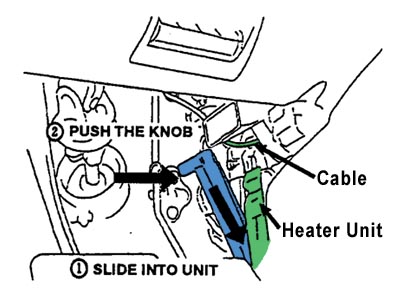

a. Reinstall the plate on the side of the heater unit using steps (1) and (2), indicated with bigger arrows to show direction in Fig. 4.

Caution: Confirm that the plate is secure.

b. Restore the carpet to its original position, taking care not to bend the cable.

Technical service bulletin courtesy of ALLDATA.

For additional tech tips, visit www.alldata.com.