Vehicles:

• 1996-2005 Chevrolet Astro Van

• 1996-2005 GMC Safari Van

Condition:

Some customers may comment on a boom-type noise heard in the vehicle passenger compartment during engine warm-up.

Correction:

Install an exhaust dampener assembly on affected vehicles. Use the following procedure and the part numbers listed below.

1. Raise and support the vehicle. Refer to the General Information subsection of the applicable service manual for information on lifting and jacking the vehicle.

Important: The exhaust dampener weight must face forward.

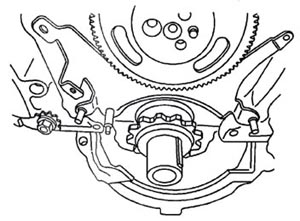

2. Position the exhaust dampener assembly on the catalytic converter pipe assembly approximately 90 mm (4 inches) forward of the outlet flange. See Figure 1.

2. Position the exhaust dampener assembly on the catalytic converter pipe assembly approximately 90 mm (4 inches) forward of the outlet flange. See Figure 1.

3. Hand tighten the clamp nut and the dampener weight while maintaining the proper position. Install three 3/8” inside diameter and 1/16” thickness flat washers, part number 11509161, or equivalent between the top of the dampener and the heat shield plate.

Note: Use the correct fastener in the correct location. Replacement fasteners must be the correct part number for that application. Fasteners requiring replacement or fasteners requiring the use of thread locking compound or sealant are identified in the service procedure. Do not use paints, lubricants or corrosion inhibitors on fasteners or fastener joint surfaces unless specified. These coatings affect fastener torque and joint clamping force and may damage the fastener. Use the correct tightening sequence and specifications when installing fasteners in order to avoid damage to parts and systems.

4. Install the 3/8-inch inside diameter lock washer, part number 11500046, or equivalent and jam nut. Tighten the clamp nut and the jam nut to 30 Nm (22 lb.ft.).

5. Lower the vehicle.

Technical service bulletin courtesy of Mitchell 1.

For additional information, visit www.mitchell1.com.